Automated Brake Test

Highly efficient shunting operation by automated processes.

The automated brake testing is no longer a vision of future. It is a today’s application.

We all live in a highly automated world. Yet in rail freight transport the clocks tick differently. Automation is a buzzword, but in rail freight cargo, automated systems are still a long way from everyday life. So we simply put the clock forward. The result: The automated brake test is a fully developed system that is already in use on 200 wagons of SBB Cargo.

The need for an automated brake inspection is given for several reasons. First and foremost is the enormous amount of time required.

Brake testing is a hugely time-consuming part of train preparation. Even today, this process remains entirely manual, making it personnel-intensive, protracted and physically demanding. However, brake testing is an unavoidable and essential part of the braking rules. Brakes must be checked following a 24-hour standstill and each time a change is made to the wagon configuration. With respect to daily routines, this means: It takes around 45 minutes for two employees to carry out a full brake test for a 500 m-long train. Brakes must be checked following a 24-hour standstill and each time a change is made to the wagon configuration. Adverse weather conditions such as rain, snow, cold, and intense heat in summer, as well as night-time operations, are additional impediments to what is already hard physical work.

The issue

Brake tests in rail freight are time-consuming, arduous and personnel-intensive: In contrast to passenger trains, the condition is checked manually. An employee has to check the applied or released brake condition several times on each axle. Brakes must be checked following a 24-hour standstill and each time a change is made to the wagon configuration. For a 500 m long freight train, it takes up to 40 minutes for two employees to carry a full brake test.

The solution

The international innovation partnership with SBB, RCG and PJM has developed an optimal solution: The "automatic brake test".

With the patented monitoring system WaggonTracker, PJM has set a new standard in the solution of the intelligent freight train. Now the WaggonTracker has been extended by the functionality of the automatic brake test. The time saving with the automatically performed brake test is enormous and amounts up to 45 minutes already for 500 m long freight trains and the automated check can be performed by only one person. For longer trains, the time saving increases. The time savings are based on the experience of SBB Cargo, where almost 200 wagons are now equipped with the automated brake testing system and are operating successfully. This creates enormous efficiency in shunting operations and saves employees the arduous check on the train itself, which was previously necessary even under the most adverse weather conditions.

How does it work?

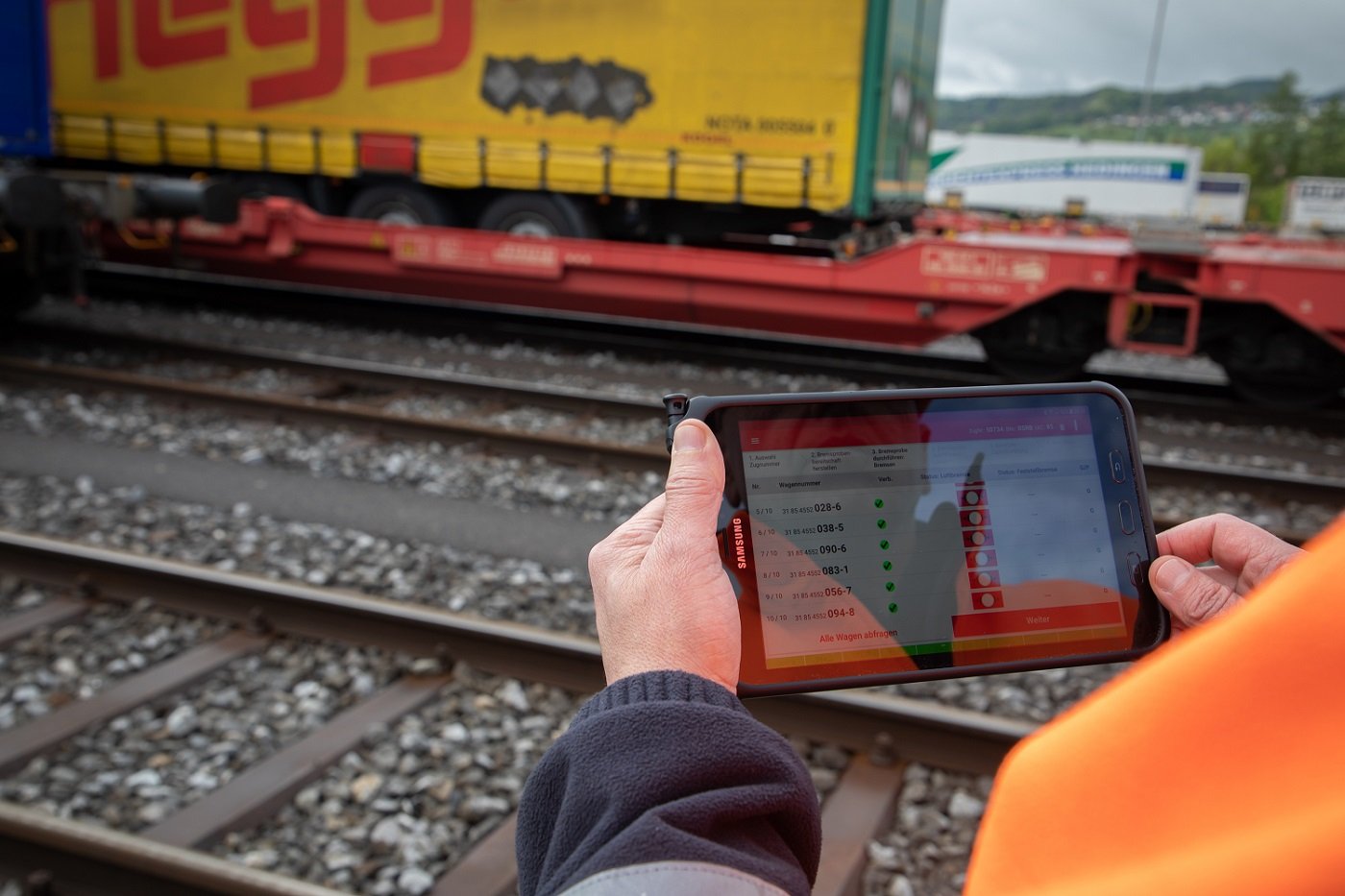

The WaggonTracker is a comprehensive monitoring system captivating by its autonomous power supply and automated process. Highly precise measurement sensors acquire relevant data on the freight train. The data is processed and visualised on a mobile terminal in real-time.

In the SBB user case, the WaggonTracker was upgraded by the feature of automated brake test. Therefore, the PJM team designed an additional sensor system enabling an automated check of the brakes. The results and analyses are shown on the tablet of the train conductor or the person in charge.

The automated brake test fulfils all safety-related regulations in terms of operation and vehicle.

Implementation steps at a glance

- The automated brake testing system is an innovation by the development alliance of SBB Cargo, PJM and Rail Cargo Austria. Currently, the system is integrated in real operation by SBB Cargo and RCG has a prototype train equipped with the automated system. Within the project AmaBPro, a pilot train of DB Cargo will be equipped with the PJM system and then operationally tested. AmaBPro is part of the program “Future Rail Freight Transport” initiated by the Federal Ministry of Transport and Digital Infrastructure. In addition, Mercitalia Intermodal will have a pilot train for intermodal transport. For SBB Cargo, the automatic brake test is an important part in the „one-person operation“ automation project. The other two parts are the early collision warning system and the automatic coupling. The automated brake test meets all safety-relevant specifications in terms of operation and vehicle.

- Since 08/2017, the pilot trains have been running at SBB Cargo. By the end of the testing, the wagons will have completed 1,000,000 kilometres. The brake test will be performed 500 times and the brakes of all wagons will have been tested 10,000 times. By now, SBB Cargo has equipped around 200 wagons with the automated brake testing system.

- 09/2021: Product development is completed.

- 02/2022: Positive evaluation without further conditions and homologation by TÜV.

In spring 2022, SBB Cargo is working on series operation. The operational processes are adapted to the new automated system, for example in the areas of training, IT or workshop.

Benefits of the automated process

- Enormous time savings: The most immediately visible impact of ABT is the time savings, which increase with train length. Around 30 to 35 minutes are saved in checking a 400 m-long freight train. At the same time, this significantly reduces the standing times for both train driver and locomotive.

- Faster round trips: Faster handling increases terminal capacities.

- Documentation: As sensors monitor the braking system during every brake test, both the brake function and state are recorded and documented.

- Enabling one-man operation: ABT allows railway companies to introduce one-man operation, for example by the train driver.

- Immediate benefit: The railway company benefits from the advantages as soon as the system has been installed and commissioned. Time savings, faster round trips, fewer personnel, etc. have an immediate impact.

- New and attractive job profiles: ABT makes the jobs of shunting personnel and brake testers more attractive. Instead of laborious and strenuous physical activity, the focus now lies on operating interactive assets.

- Digitalization in rail freight cargo raises desperately needed competitiveness. ABT is a crucial investment and innovation which offers huge advantages to every user. It is essential in economic terms as it not only renders rail freight cargo more cost efficient, but also makes an important contribution to achieving climate goals.

Get more on the automated brake test and watch the video

Will be a thing of the past quite soon: The manual brake test which is time-consuming and exhausting.

Contact

Felix Egger-Cimenti

More information on Automated Brake Test ...

You are interested in further information? Please fill in this form or contact us directly.