Testing the IR6000 for vehicle approval in India

The project at a glance

PJM, the expert for worldwide railway solution, was in charge of testing the vehicle dynamics of the TR6000 for vehicle approval. The IR6000 was engineered by GE Transportation systems, PJM's customer was Indian Railways. The state-of-the-art diesel-electric locomotive is planned to be in operation extensively. In all projects, PJM strives to minimise the risks. Thus, PJM is the only supplier worldwide involving hardware in the loop-simulations.

As early as in the run-up to a project, hardware in the loop.simulations are the decisive details which is provided by PJM only. Hence it is possible to forecast the wheelsets's performance, e.g. in the field of measurement uncertainty. The customers' befenit is to drop unnecessary risks.

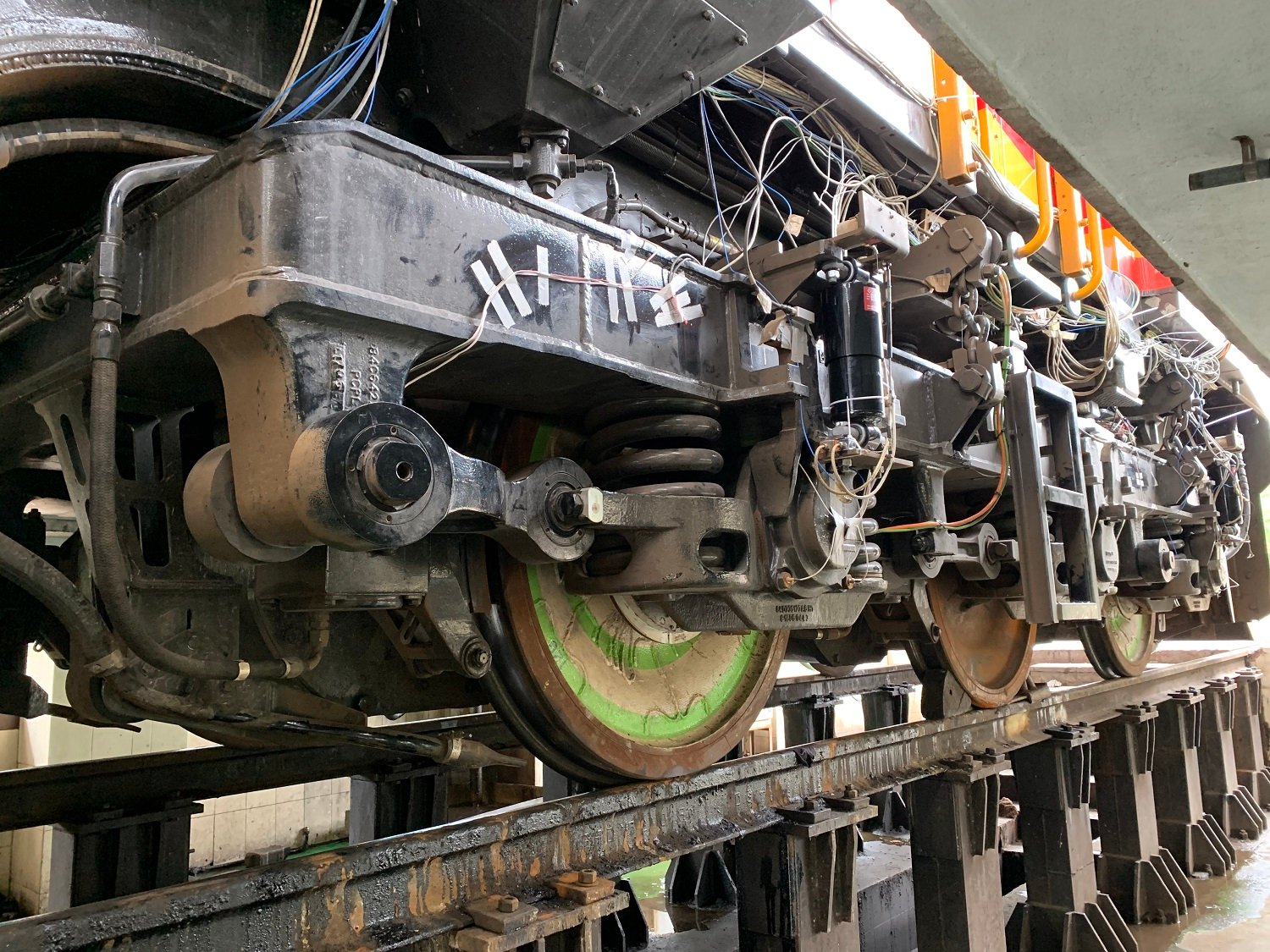

To measure the vertical and contact forces of wheel discs, the wheel set was designed and built in Graz. There were several challenging aspects: The big wheel diameter, the very confined space du to the gear unit mounted on the axle and the weight of the wheel sets which is three times higher compared to common wheel sets.

First station was Erie in the USA, the home base of GE Transportation Systems. There, GE designed and built the state-of-the-art diesel-electric locomotive meeting the high TIER 2 emissions standard. In the factory, our team installed the wheel set on the locomotive. Then, the wheel set was shipped to Hyderabad in India for the test runs.