PJM performed tests for approval of Stadler FLIRT vehicles for the regional railway TILO

The project at a glance

The railway line seems to taken from a fairy tale. The regional railway TILO provides trans-regional mobility between Switzerland and Italy by connecting the villages of Ticino and Lombardy. In this picturesque landscape, 40 FLIRT trains of Stadler haven been on the track. In order to keep a high level convenience, the rail fleet was enlarged with further FLIRT trains of the latest generation. For the approval tests of vehicly dynamics, Stadler Bussnag AG settled on the many years' experience and reliability of PJ Messtechnik GmbH (PJM).

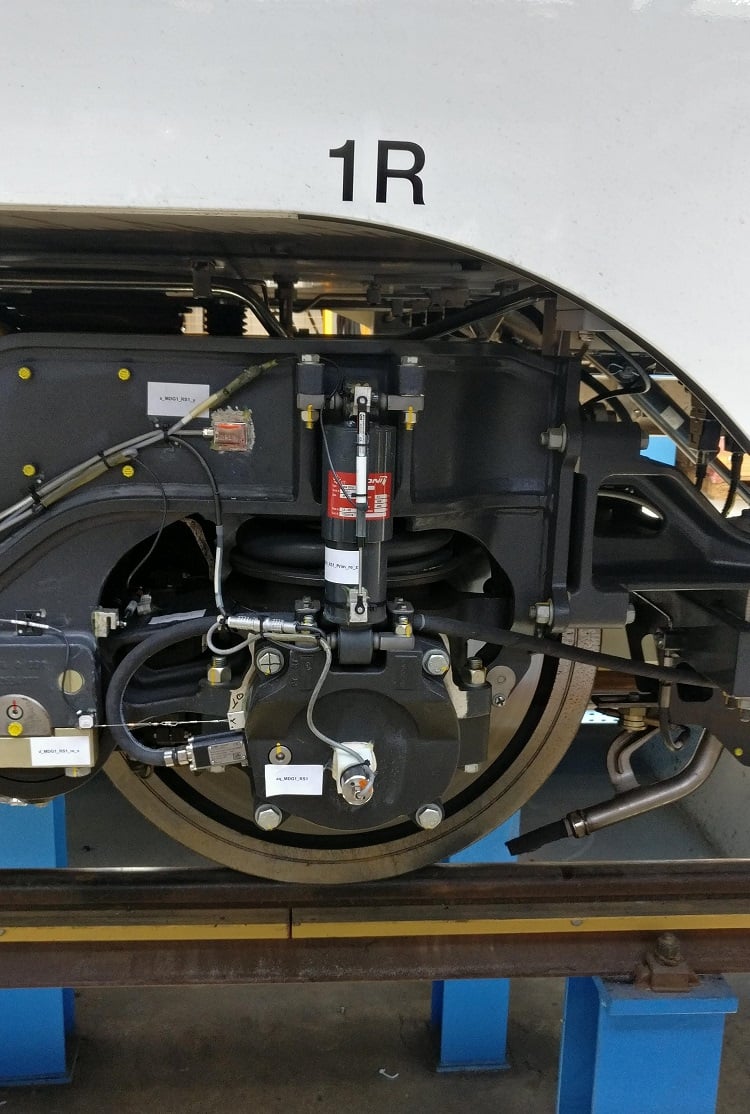

The full-service provider for railway system solutions is a testing facility accredited by EN ISO/IEC 17025:2017. Due to a large number of worldwide projects, PJM has gained comprehensive know-how in terms of country-specific standards and regulations. Vehicle dynamics includes testing the track load and security regarding running safety. Therefore, various failure conditions have to be checked, such as a breakdown of the air spring or of the damper. Both components have a strong impact on the running behaviour. Above all, the components are crucial factors for comfort and safety. Close attention was paid to the conditions of contact of track and wheel. Within this, the evaluation of the running characteristics under increased equivalent conicity is a very demanding process. This evaluation is required by EN14363:2016 and it takes a many years’ experience and expert knowledge. What’s the process? Beforehand, assessments are conducted. The test rides are performed, including simulation and testing of various failure conditions. Finally, all those assessment parts are put together to an overall picture.

Riding comfort is an important factor in terms of running characteristics. But highest priority is safety. Even when it comes to breakdowns – e.g. of the air spring – it is necessary to ensure a safe transport to the next railway station.

The PJM-team performed the comprehensive tests in Switzerland, on the world-famous Gotthard railway amongst others. Due to the preliminary work and a very exact planning, the tests were finished after 6 weeks.