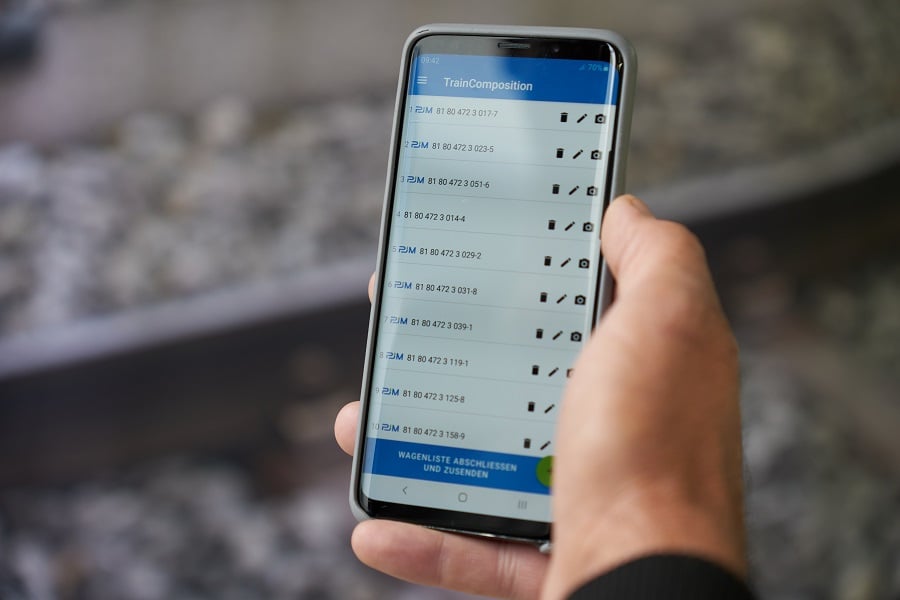

We are live at Rail Live 2021 in Madrid! On the booth of our industry partner Pilz GmbH, automation will be in the limelight. We present our digital overall system WaggonTracker which combines monitoring and automated brake test or automated load monitoring. There will be a presentation on the digital technology on the automated brake test (1st of December, stage 4). The two experts Gerhard Moser, Senior Manager Systems Integrations of Pilz GmbH and Christoph Lorenzutti, COO of PJ Monitoring, will talk about the solution for digital rail freight.

Get your free ticket: https://www.terrapinn.com/conference/rail-live/index.stm

We are looking forward to your visit at booth 82!