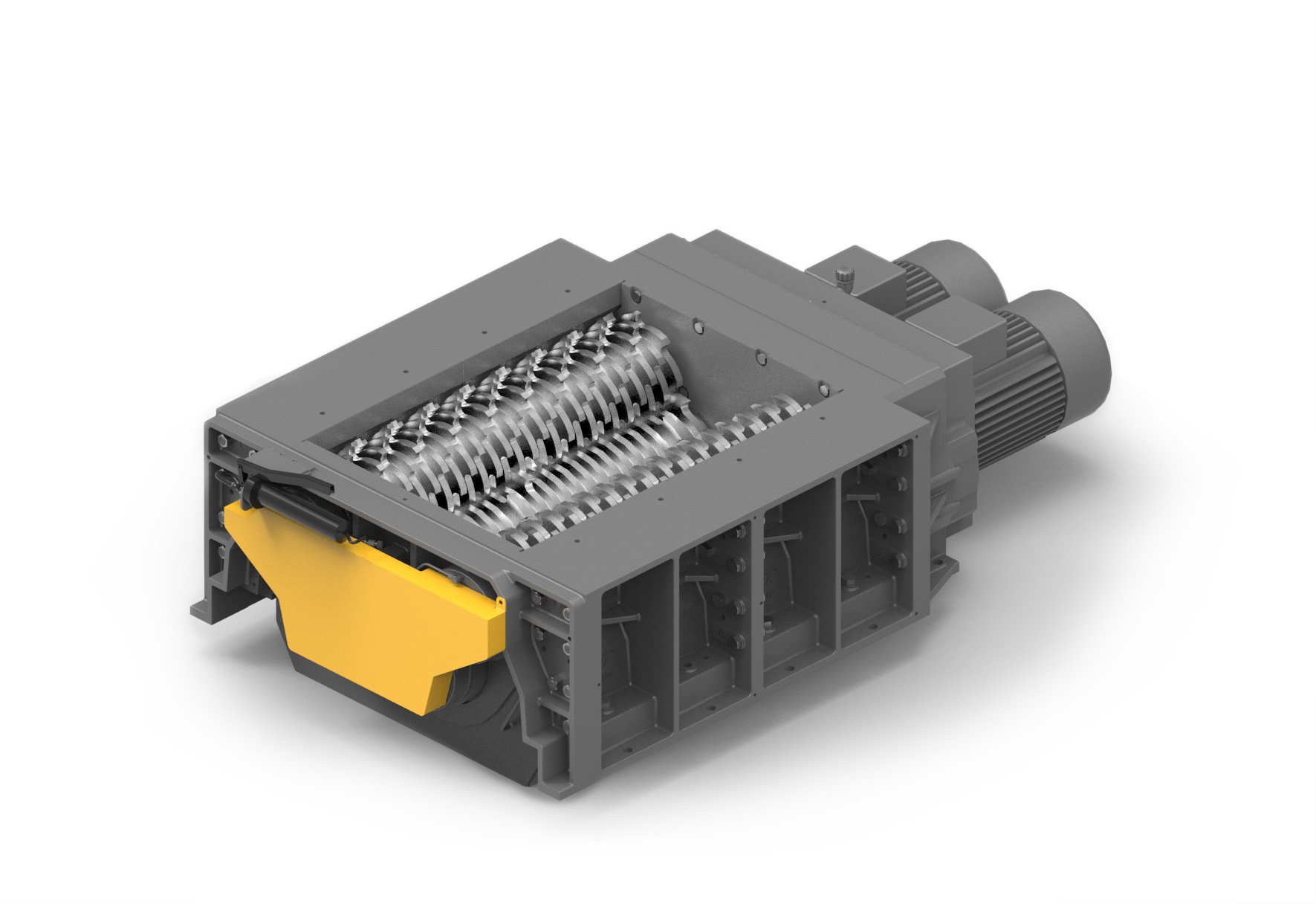

UNTHA is a well-known company specialised to design and construct industrial shredders. The areas of application range from recycling of waste wood and organic waste to many more recyclable materials. To shredder various types of metal, it needs high-performance shredders. When it comes to measure the strains and stresses of the shredder machines, UNTHA has counted on the know-how of PJM for various times. Recently, PJM had tested the metal shredder machines with 2 and 4 shafts. During the test phase, the torsional vibrations are tested while shredding different types of material. For long-term measurement, the test phase may take several weeks. The measurements of each shaft provide crucial results finding their way into further developments of the machines, e.g. to determine the level of motorisation.

The great challenge in measuring shredder machines is to link the contrast: The shredder process is very rough, yet the very sensitive devices must provide precise and reliable data.

Shredded material is the basis for reusing and recycling which is a crucial contribution to protect the environment protection and conservation of resources. We are proud of being part of this contribution!