The instrumented wheelset expertise is made up of several elements that PJM combines with each other. PJM perfectly matches measurement technology, experience as an ISO/IEC 17025 accredited test centre, engineering expertise and 10 years of experience in the development and production of measuring wheelsets.

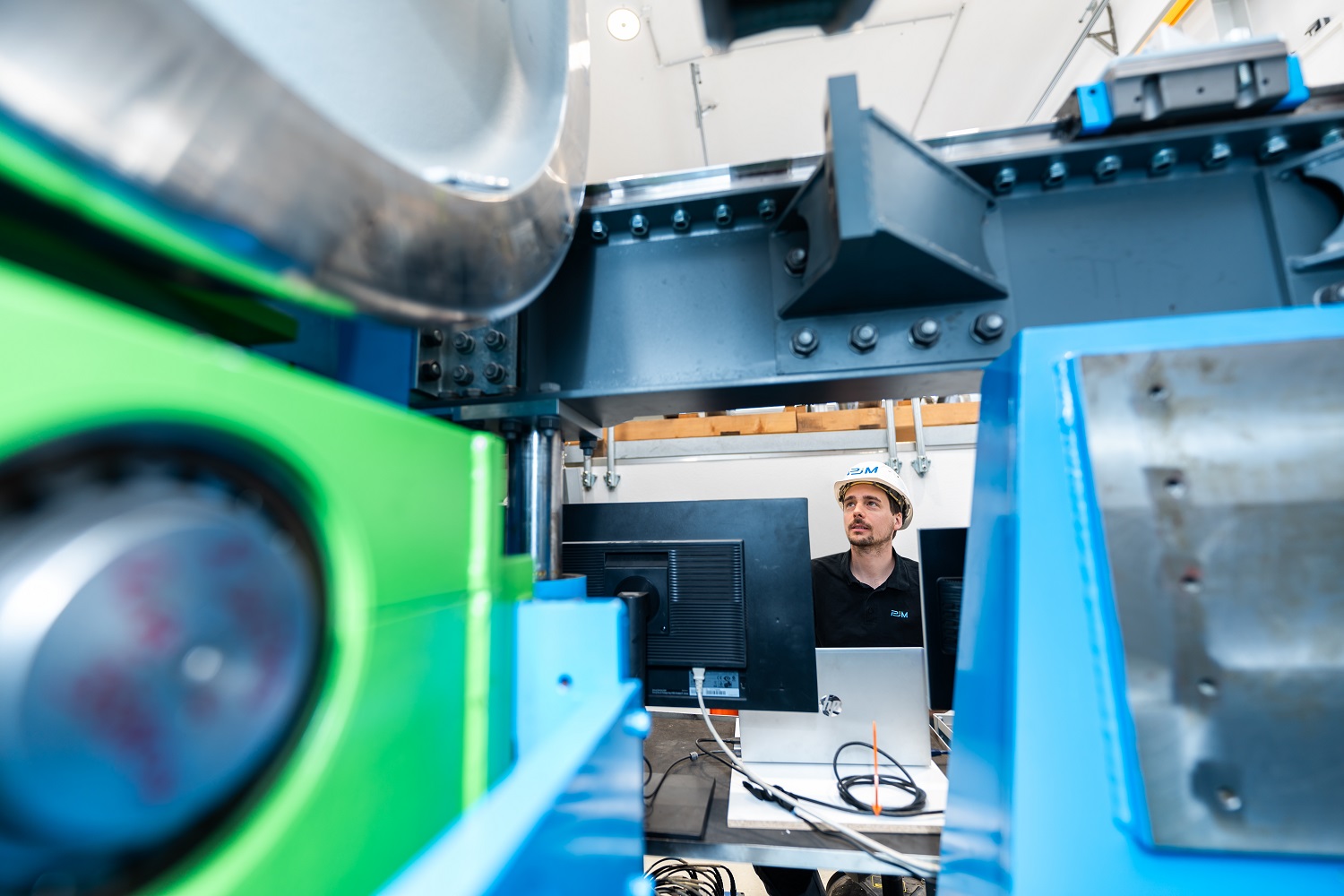

PJM has now also raised its infrastructure and technical equipment to a new level. The new part of the building has been equipped with a comprehensive range of equipment to ensure the highest levels of precision, stability and standard in metrological terms. In addition, the expanded infrastructure will enable even faster throughput times and project processing in future. The equipment includes, among other things

- Mobile test rig for measuring wheelsets for all track gauges and calibration during test runs on site

- Premises for the parallel production of 12 instrumented wheel sets

- Indoor crane and two electric forklifts

- ESD-protected working environment

- Air-conditioned room (for consistently ideal conditions, for example when attaching strain gauges)

- Dynamic test rig for end-of-line testing of instrumented wheel sets

- Fine balancing in accordance with ISO13260 limits

‘The dovetailing of theory with practical testing experience is a great added value for our customers,’ says Martin Joch. He continues: ‘The instrumented wheelset infrastructure guarantees the highest measurement quality for every phase and every requirement. In combination with our specialised knowledge in engineering and our many years of experience in dynamic testing, we offer vehicle manufacturers a considerable portfolio of knowledge and services.’

This makes PJM a strong partner in the field of measuring wheelsets:

- All processes and project steps relating to measuring wheelsets are handled by PJM in-house and from a single source

- This also results in short throughput times

- Calculation, design, production, calibration and balancing

- Powerful telemetry system: Thanks to the extensive equipment, 12 measuring wheelsets can be operated simultaneously

- PJM offers solutions for every application and every wheel geometry (not just standard solutions)

https://pjm.co.at/en/wp-content/uploads/sites/2/2024/05/PI-PJM-Messradsatzhalle-5-2024-EN-Web.pdf