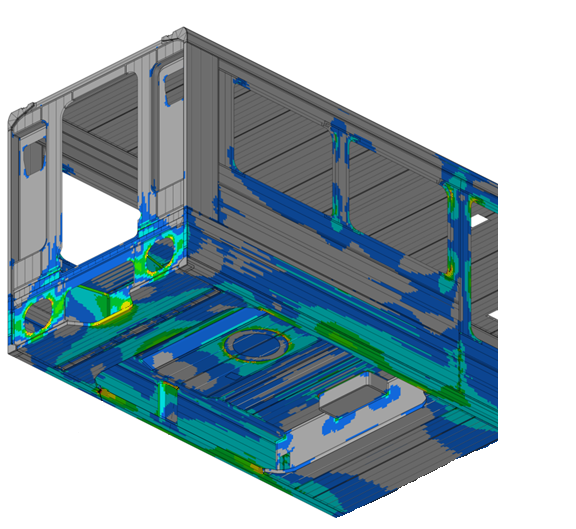

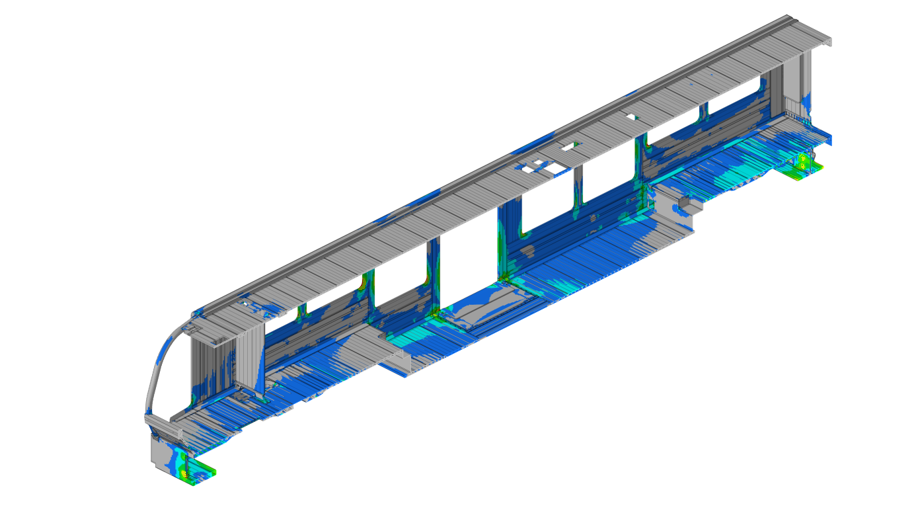

In the development of rail vehicles, a key factor is: as little material and weight as necessary, but as much load-bearing capacity as possible. Topology optimisation has been part of our everyday engineering work for years. Among others, Stadler Rail AG relies on our calculation know-how. In a current project, our engineering team is dealing with structural optimisation and strength verification of the wagon bodies of a local transport vehicle.

We think out of the box

We have a particularly effective and efficient engineering team, as experienced experts in design, calculation, simulation and certification work very closely together. Expanded by measurement technology specialists, we offer unique know-how in the product development of structural railway components. Our innovative strength is further enhanced by our distinctive out-of-the-box thinking: All engineering staff have many years of experience in the automotive and mechanical engineering sectors in addition to their railway activities. Therefore, we are not only engineering experts in rail transport, but also in projects in other sectors, such as the optimization of waste treatment plants or other mechanical engineering projects.

Best calculations for the future

With our concentrated knowledge in calculation, simulation and measurement, as an accredited testing laboratory we are well prepared when calculations and simulations are increasingly used for the approval of railway vehicles in the future. For all this, FprCEN/TS 17833:2022 comes into play, the "Guideline for the use of simulations to demonstrate compliance with technical and regulatory requirements".

We seamlessly dovetail our profound experience from worldwide test drives and approval trials with our engineering know-how. We link our empirical values from track tests with our design knowledge and thus create great added value for our customers.