WINDHOFF relied on PJM's experience and expertise to test an innovative, modular multi-purpose vehicle within a short time frame.

The German specialist for rail vehicles, railway and shunting technology has developed the next generation of a multi-purpose vehicle. WINDHOFF Bahn- und Anlagentechnik GmbH had commissioned the Austrian system specialist PJM to carry out the test runs for approval on the German rail network. As an accredited test center in accordance with ISO/IEC 17025, PJM carried out vehicle tests in the areas of braking and running characteristics as well as static tests to determine derailment safety and wheelset torsional vibrations.

MPV®-VentuS® is a modular system that can be used to create a wide variety of vehicle configurations. The range of working modules includes various cranes, platforms, contact wire pusher, but also containers or contact wire measuring systems. The power system also has a modular design so that adjustments can be made very easily over the course of the vehicle's service life and, for example, a vehicle that is currently diesel-electric with a generator and electric motor can be converted to all-electric at a later date. The MPV®-VentuS® vehicle family is designed on the basis of DIN EN 14033 and authorized with the European TSI homologation. The MPV®-VentuS® type GAF, which was tested together with PJM in Austria last year, is a track maintenance vehicle for Deutsche Bahn (DB). The vehicle was officially presented at InnoTrans 2024, and in February 2025 Windhoff and DB received authorisation to place the MPV VenuS GAF modular ancillary vehicle on the market. The vehicle is approved on the basis of the European TSI from the 4th railway package.

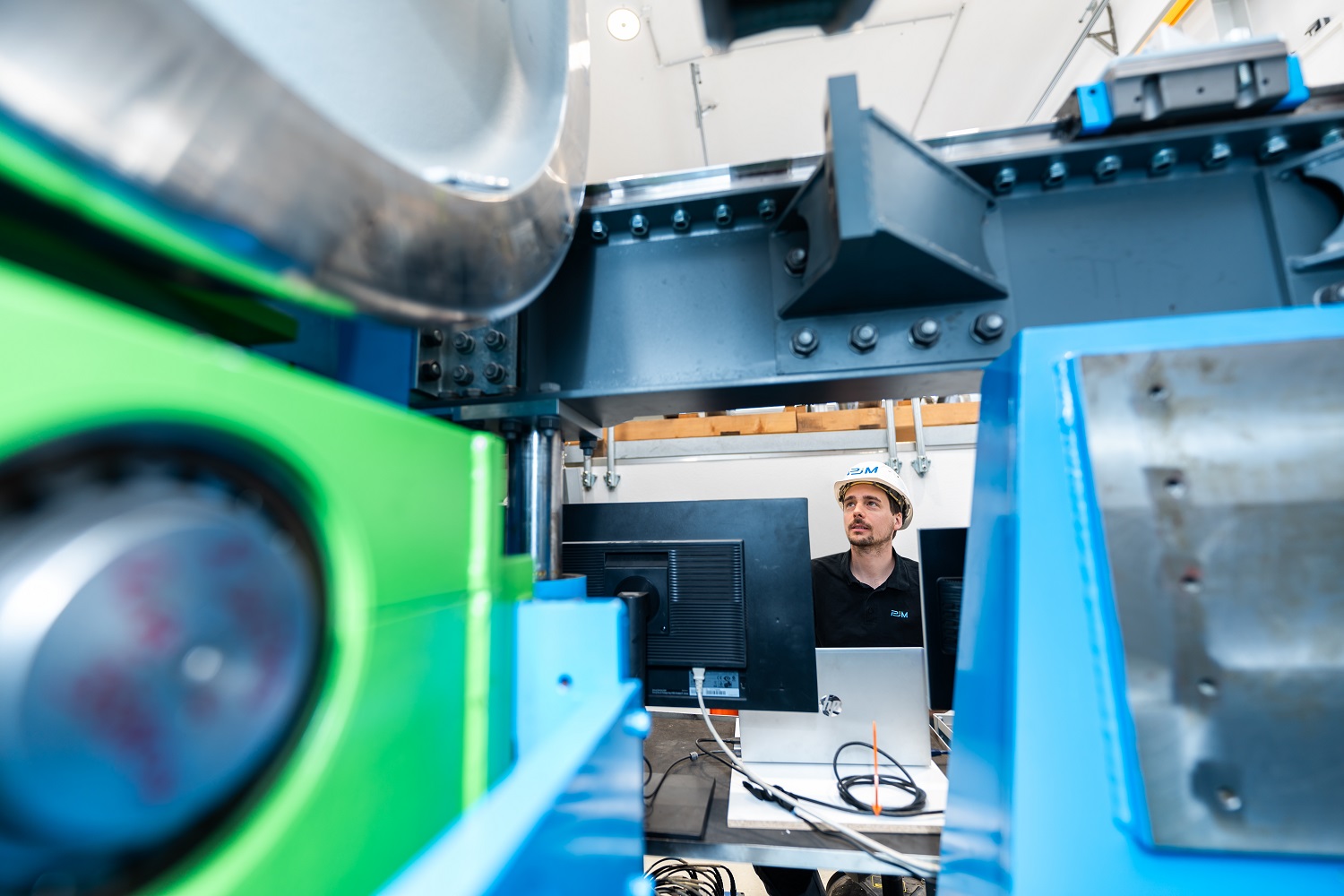

‘It is important to us, to complete our customers’ projects just in time and successfully. For WINDHOFF too, we were able to carry out the vehicle tests and analyses within a short time frame,’ says Martin Joch, CEO of PJ Messtechnik GmbH.