From 2 - 5 June, transport logistic 2025 in Munich, the world's leading trade fair for logistics, mobility, IT and supply chain management, will be another industry highlight on the agenda. PJM will of course be there - with the WaggonTracker, the smart solution for digital freight transport, and specialist expertise in testing rail vehicles.

When the industry experts meet in Munich to discuss the mobility of tomorrow, PJM will be presenting its system solutions for the entire development, testing and approval process for rail vehicles.

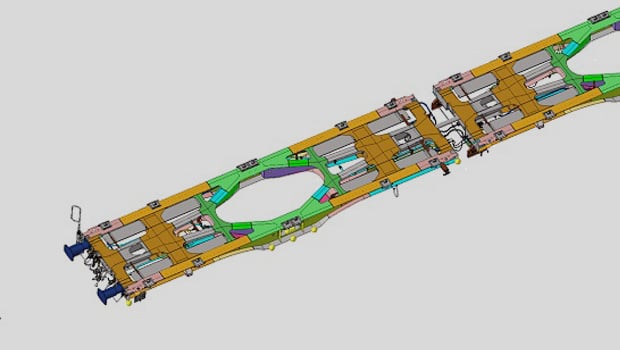

With our digital overall system WaggonTracker, we provide on-site answers to the burning questions in the field of automation and digitalization in freight transport: How can we succeed in saving costs and being more competitive? How can safety be increased? The digital train functions such as real-time brake analysis and brake system monitoring, real-time kingpin monitoring, IDDS derailment diagnostics paired with real-time in-train communication (direct communication with the train driver), load weight monitoring and automatic brake testing create clear advantages that have already convinced numerous freight wagon rental companies and manufacturers, railway companies and rail logistics companies.

Do you have questions about the digital goods train or other topics such as authorisation, engineering or project management? The specialists from the PJM Group will be there for you at transport logistic 2025:

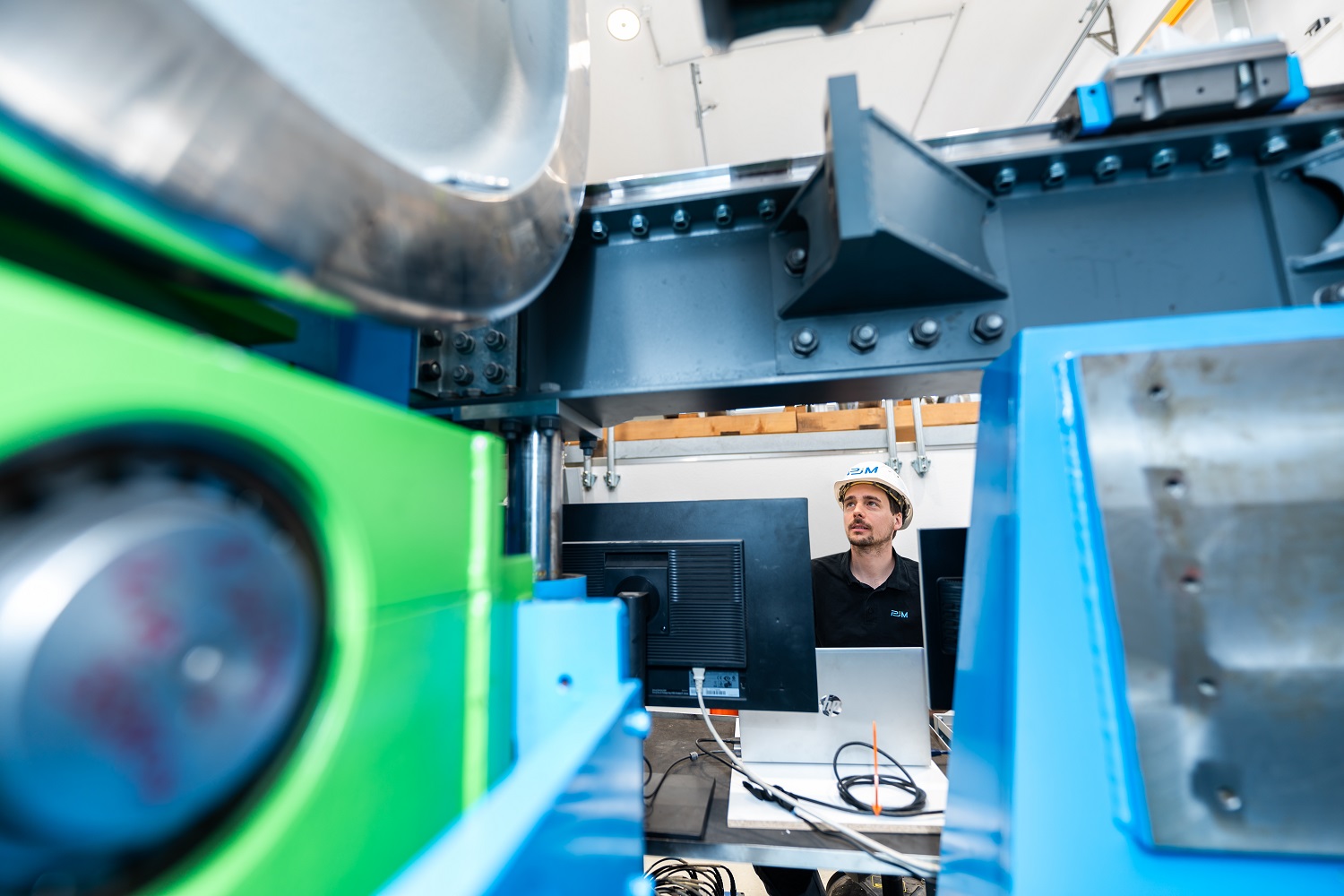

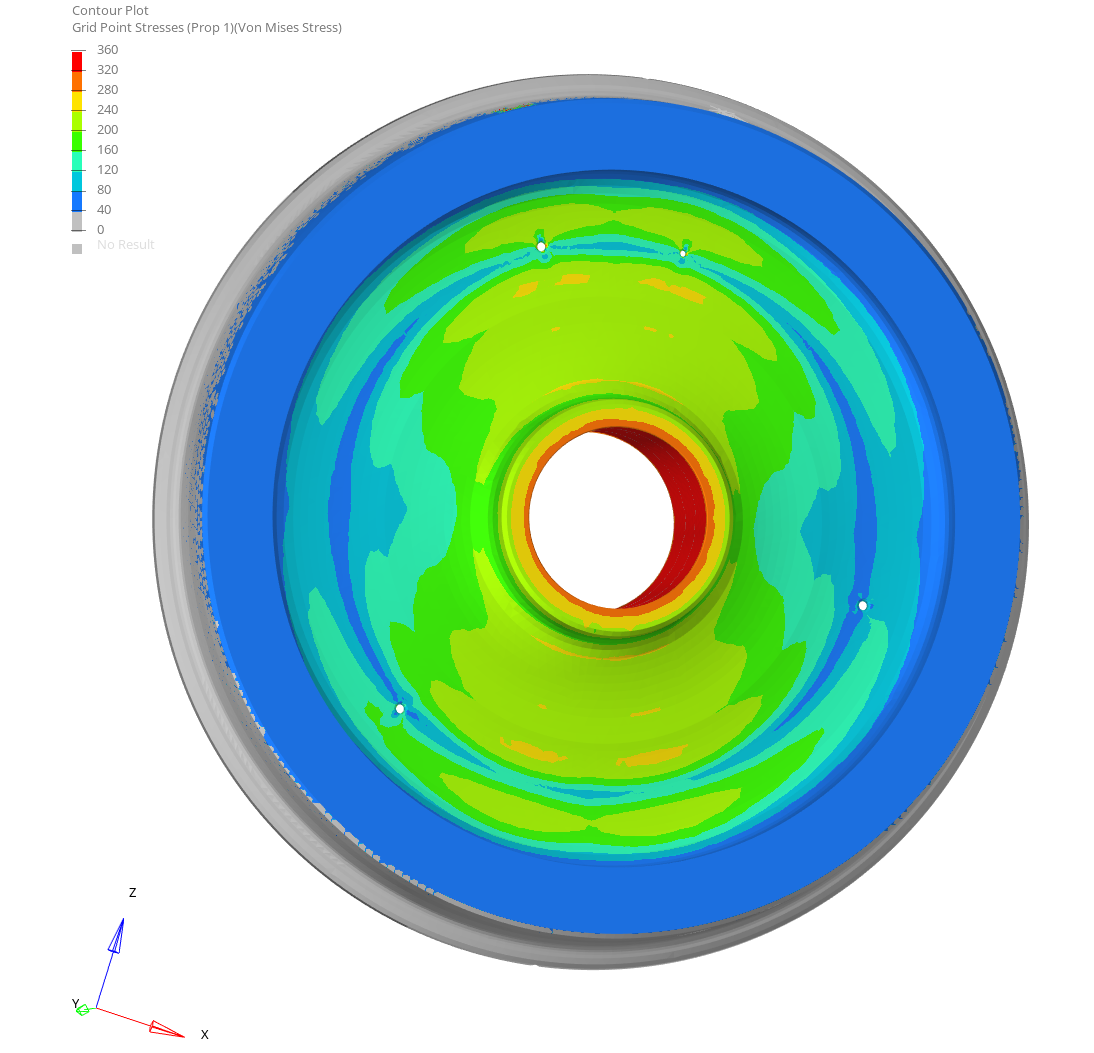

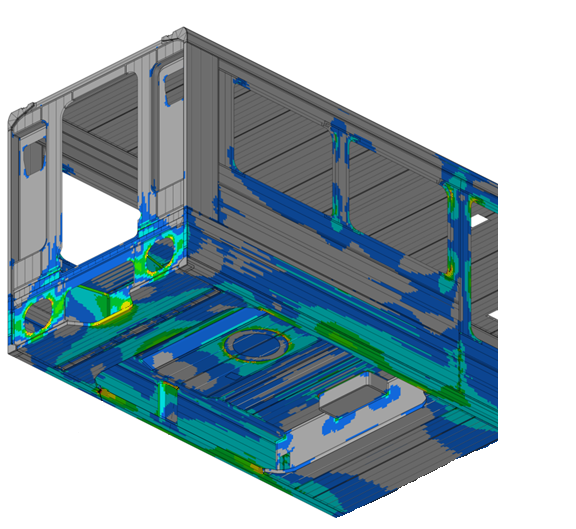

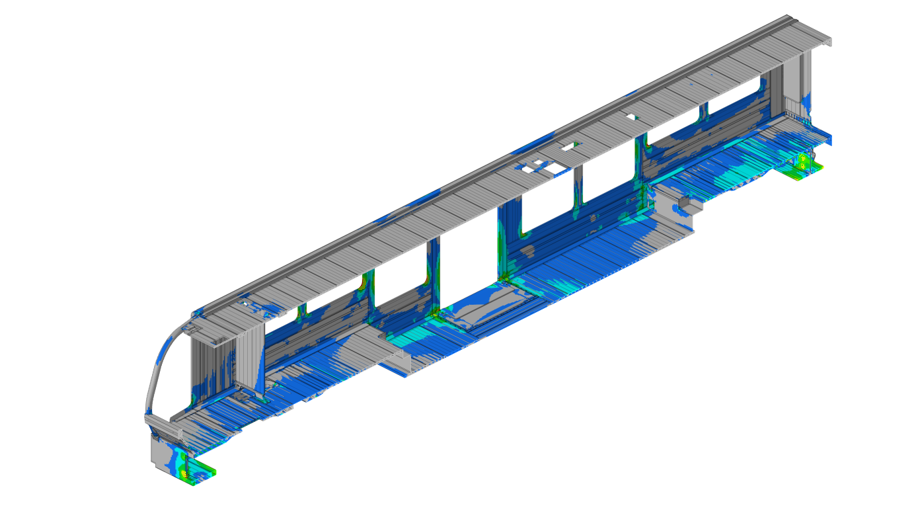

- As an accredited test centre in accordance with ISO/IEC 17025, PJ Messtechnik GmbH carries out tests worldwide for the approval of rail vehicles and offers engineering expertise for the product development of structural railway components.

- With its WaggonTracker system, PJ Monitoring GmbH is a technology leader in the automation and digitalization of rail freight transport.

- PJ Motion GmbH specializes in authorization and project management in accordance with the 4th railway package for track-bound vehicles.

- RCC Railway Competence and Certification GmbH is an accredited conformity assessment body in accordance with ISO/IEC 17065 and ISO/IEC 17020 and specializes in certifications and safety assessments.

Visit us at stand B6.116 - we look forward to seeing you!