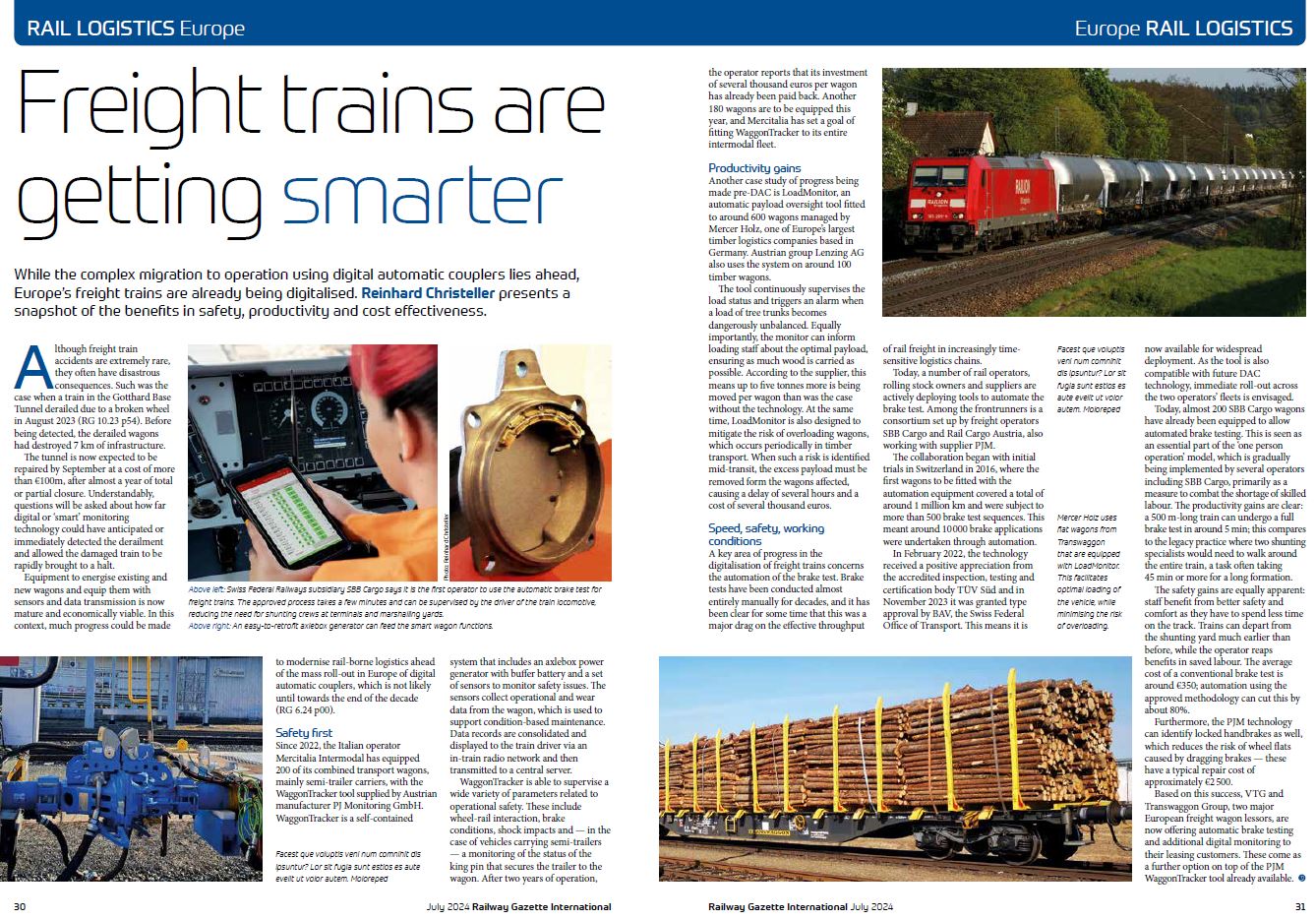

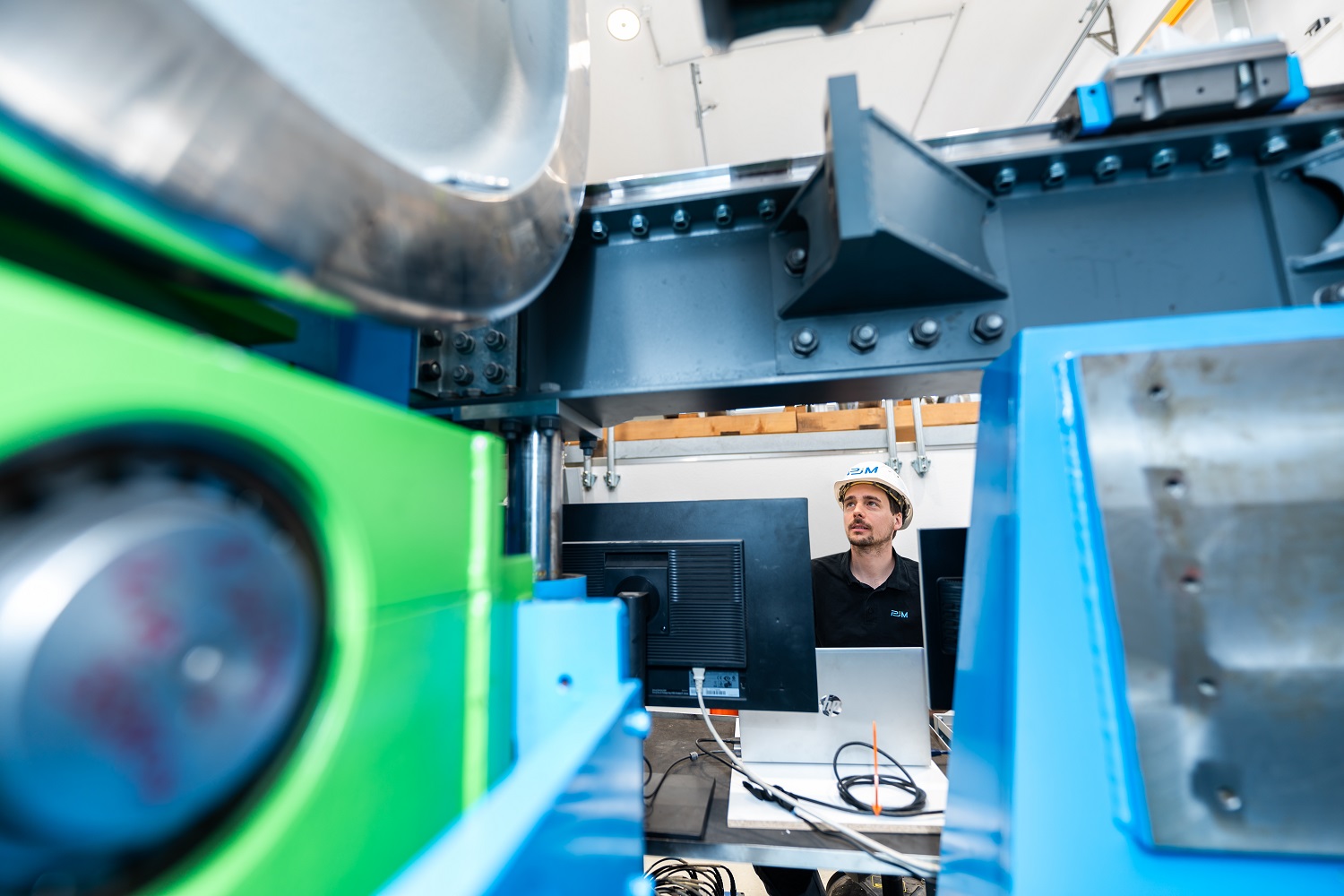

The international railway magazine Railway Gazette analyses the digitalisation of goods trains in Europe and takes a detailed look at our smart goods train concept. Get the in-depth article on the development steps and benefits of intelligent freight trains.