We have packed our highlights of 2024 into a PJM review 2024. 1 year in 1 minute to look back on.

Styrian Future Conference 2024: PJM takes part as innovation award winner

Companies and scientific institutions from Styria are coming together this year under the motto of cooperation. The Future Day is a platform for new ideas, knowledge exchange and future-shaping projects. The “Future Day” is organized by SFG, the Province of Styria and JR.

PJM has been invited as a winner of the Innovation Award 2024 and will put the spotlight on its unique automatic brake test. It is the first and only approved system that automates a complex, manual process. The brake testing system is already in use at SBB Cargo and on board of several pilot trains in Europe.

Automated rail freight transport is crucial in order to become more attractive, competitive, faster and safer and to cushion the demographic-related shortage of skilled labor. The focus is also shifting to environmentally friendly rail transport in order to achieve the climate targets that have been set.

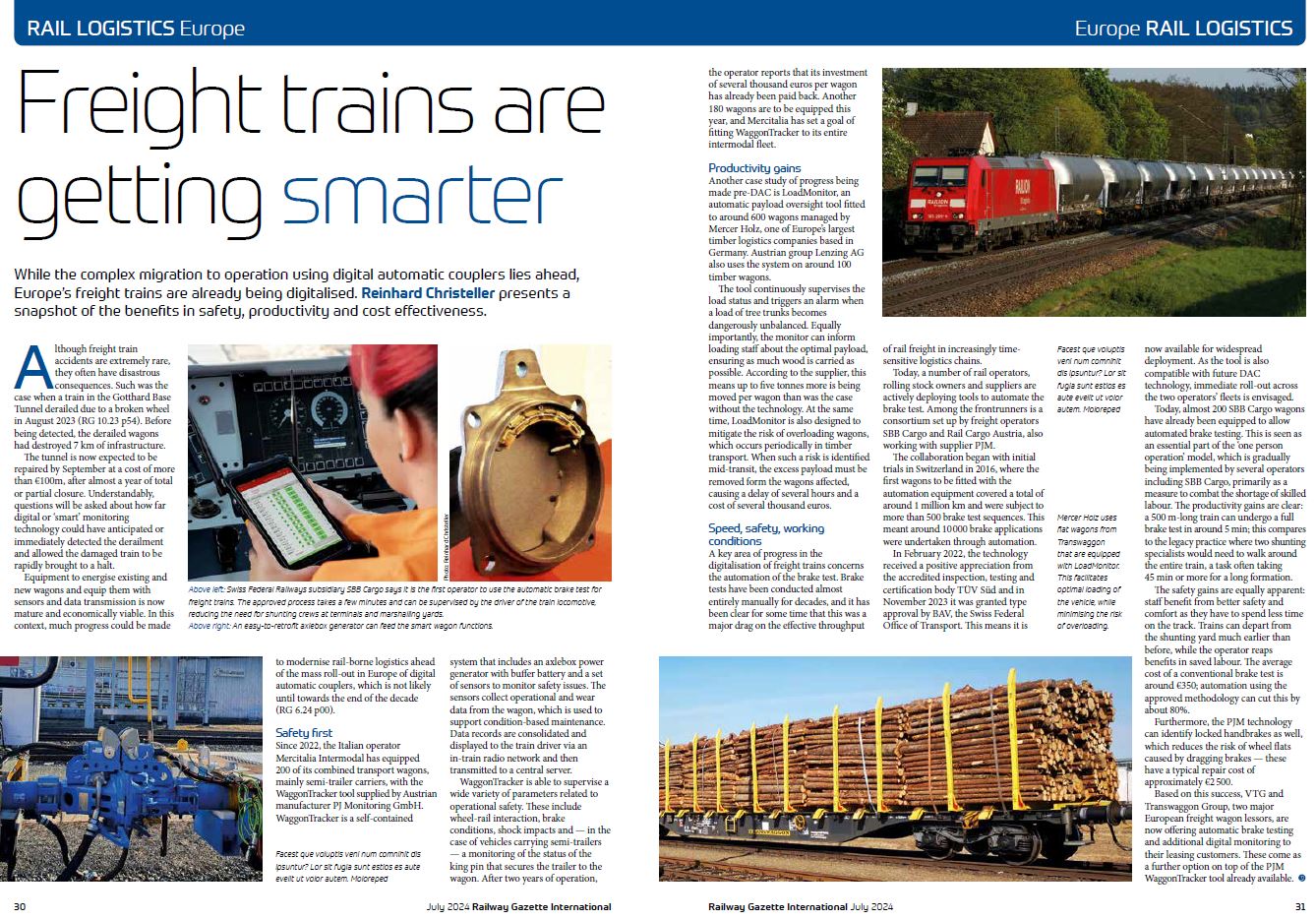

Railway Gazette provides an in-depth article on smart train technology

The international railway magazine Railway Gazette analyses the digitalisation of goods trains in Europe and takes a detailed look at our smart goods train concept. Get the in-depth article on the development steps and benefits of intelligent freight trains.

State Prize for Digitalisation 2023 for PJM

A railway project was honoured with the Austrian State Prize for Digitalisation 2023. The automatic brake testing system from PJM emerged as the winner in the ‘Digital Transformation and Innovation’ category. State Secretary Claudia Plakolm and Harald Kräuter, ORF Director of Technology and Innovation, presented the award to CEO Günter Petschnig and COO Christoph Lorenzutti from PJ Monitoring GmbH.

‘We are delighted to receive this award for two reasons. The fact that a rail project was honored underlines the importance of rail freight transport in an economic and climate policy context. 10 years of development work, high investments and perseverance have been rewarded. This is great recognition for our entire team,’ says Günter Petschnig. He adds: ‘SBB Cargo is a great development partner. Such complex projects can only be successfully completed if all project partners pull together. A big thank you for the commitment, the belief in the technology and the great collaboration.’

‘The quality of the projects awarded this year as part of the State Prize for Digitalisation is impressive. You can see how much innovative strength there is in Austria in this core area, which is crucial for a successful future. I am delighted that we have been able to bring some particularly outstanding ideas to the fore with today's awards. On behalf of ORF, I would like to congratulate all of the award winners,’ emphasised Harald Kräuter, ORF Director of Technology and Innovation.

The jury of experts evaluated the open-topic submissions according to a catalogue of criteria such as degree of innovation, quality of implementation, high usability, added value for users and market potential. The submission phase was organized by the FFG (Austrian Research Promotion Agency). The jury's statement: ‘The submission Digital Rail Transport - Automated Brake Test enables the digitalization of the previously manual inspection of brakes in rail transport using special sensor technology and remote evaluation via mobile operating devices. This reduces the manual effort and duration of the brake test. By automating this inspection process, the physical strain on staff and the time required for the inspection are reduced. This means that the rolling stock can be put back into service more quickly and enables rail transport capacities to be increased. This patented system has already been approved and is being used successfully by the SBB Cargo.’

‘The State Prize for Digitalisation shows that Austria is a strong location for digital innovations. We must continue to develop our qualities in a targeted manner and, above all, further strengthen digital skills throughout Austria. They are an important basis for successful digital transformation and innovative companies. I would like to congratulate all the award winners who are making new digital success stories possible for the whole of Austria and are attractive role models for other companies and institutions,’ said State Secretary for Digitalisation Claudia Plakolm.

‘Digitalisation is a decisive factor for growth and broad prosperity, which we must use in a targeted manner in Austria. Openness to technology is the indispensable basis for innovations that secure our competitiveness and thus our entire way of life. I am impressed by the achievements of the award winners and congratulate them warmly. Because they tackle and implement - that is the right spirit for the future,’ said a delighted Federal Chancellor Karl Nehammer.

Nomination for the State Prize for Digitalisation

The most innovative digital projects and products were sought, evaluated and selected by a top-class jury according to a wide range of criteria. The submission phase took place together with the FFG (Austrian Research Promotion Agency). We are delighted that our project "Digital Rail Transport: Automatic Brake Test via Tablet" has been nominated. The decision on the State Prize Digitalisation 2023 will be made at the JOYN ORF 4GAMECHANGERS Festival 2024.

Watch live on TV or via Facebook:

14 May 2024 at 8.00 pm

Further (German) information on: https://www.digitalaustria.gv.at/WissensWert/Events-Digital-Austria/Staatspreis-Digitalisierung.html

Innovation Award for automated brake testing system

The brake testing system is the best digital project and was honoured with the Innovation Award 2024. The coveted award was presented by Barbara Eibinger-Miedl, member of the Styrian government, and Christoph Ludwig, Managing Director of SFG.

Renowned jury members, including Sabine Hertlitschka from Infineon Technologies and representatives from institutions such as the Austrian Patent Office, the Institute of Industrial Science and AWS, determined the most outstanding projects in the categories of sustainability and digitalization in a two-stage selection process. The assessment criteria included innovation content, overall economic effect and market opportunities.

The award was combined with a personal visit from the Provincial Councillor for Economic Affairs, who not only showed great interest in the automatic brake test, but was also impressed by the entire PJM service portfolio, the headqaurters and the technical equipment. Provincial Councillor Eibinger-Miedl warmly congratulated and emphasised: "Mobility in particular is a field of strength in Styria and PJM is one of the innovation companies." Günter Petschnig was delighted with the award. "We have a great team and a great network with our partners such as SBB Cargo. We have had massive investments for developing the automatic brake test and further innovations, and we keep drive forward new technologies. The award is a great pleasure for us!"

Photos: With courtesy of SFG / Oliver Wolf

TRANSWAGGON includes automatic brake testing and digital monitoring as equipment option

Together with PJM, the TRANSWAGGON Group is making a key contribution to the automation and digitalization of rail freight transport in Europe. Wagon rental customers save time and increase safety in operation by equipping their wagons with automatic brake testing. Many other digital monitoring features are available for TRANSWAGGON customers. In addition, the energy self-sufficient and powerful WaggonTracker system can be expanded with customer-specific systems. The integration of automatic brake testing and monitoring functions into the TRANSWAGGON Group's equipment portfolio is a logical step.

"The automatic brake test saves time and increases safety during operation. It eliminates the need for a time-consuming walk around the entire train. Train preparation can therefore be carried out more quickly and safely," says Bertram Wieloch, CTO and member of the TRANSWAGGON Group's Executive Board.

This is not the first cooperation between the TRANSWAGGON Group and the Austrian system specialist PJM. In the past, around 500 wagons were equipped with the so called LoadMonitor, an automatic load weight monitoring system, on behalf of Mercer Holz. The system analyses the load weight during the loading process and visually indicates the maximum load capacity. Since then, one of Europe's largest timber logistics companies has benefited from a better capacity utilization, avoids overloading thanks to the precise data and appreciates completely paperless documentation.

Photo: With courtesy of TRANSWAGGON Group

FS Logistics Business Unit continues fleet upgrade with PJM’s smart train portfolio

Combining transport efficiency with safety is an important requirement for Mercitalia Intermodal in daily intermodal transport. The Italian wagon operator has therefore been focusing on digital monitoring functionalities and automated processes for several years. The transformation of the existing fleet into Smart Train freight wagons is being systematically implemented. This year, at least another 180 wagons will be modernized, while around 200 wagons - mainly of the T3000 type - have been upgraded in the past two years. Mercitalia Intermodal began upgrading its freight wagon fleet back in 2017.

The benefits of the Smart Train functions are far-reaching: shorter delivery times thanks to automated processes in the track environment, predictive maintenance logic and condition-based maintenance models reduce costs while increasing reliability, efficiency and the general safety of rail transport.

1 year in 1 minute: The PJM review 2023

Our teams worked on 90 projects, we grew and fully automated a process for the first time in the history of rail transport. A short video portrait of our numerous activities this year.

2nd award for the "Smart Train" from Mercitalia Intermodal

2nd award for the "Smart Train" from Mercitalia Intermodal

The smartest goods train in Europe has been honoured for the second time. Following the Austrian Mobility Award 2023, which was presented to Günter Petschnig and Christoph Lorenzutti in Vienna in September, Mercitalia Intermodal - Polo Logistica Group FS was honoured as "Logistico dell'Anno 2023" in Italy. The goods train is equipped with a wide range of monitoring and automation functions based on PJM's WaggonTracker system. Congratulations!

Details & all functions of Europes most intelligent goods train

Be up to date with our periodical newsletter

Monitoring

Testing Center

Metrology

Products

Engineering

PJ Messtechnik GmbH

PJ Monitoring GmbH

Waagner-Biro-Straße 125

8020 Graz

Austria

Tel.: +43 316 228454

Fax: +43 316 228454-15

[email protected]

© 2026 PJ Messtechnik, PJ Monitoring. All rights reserved