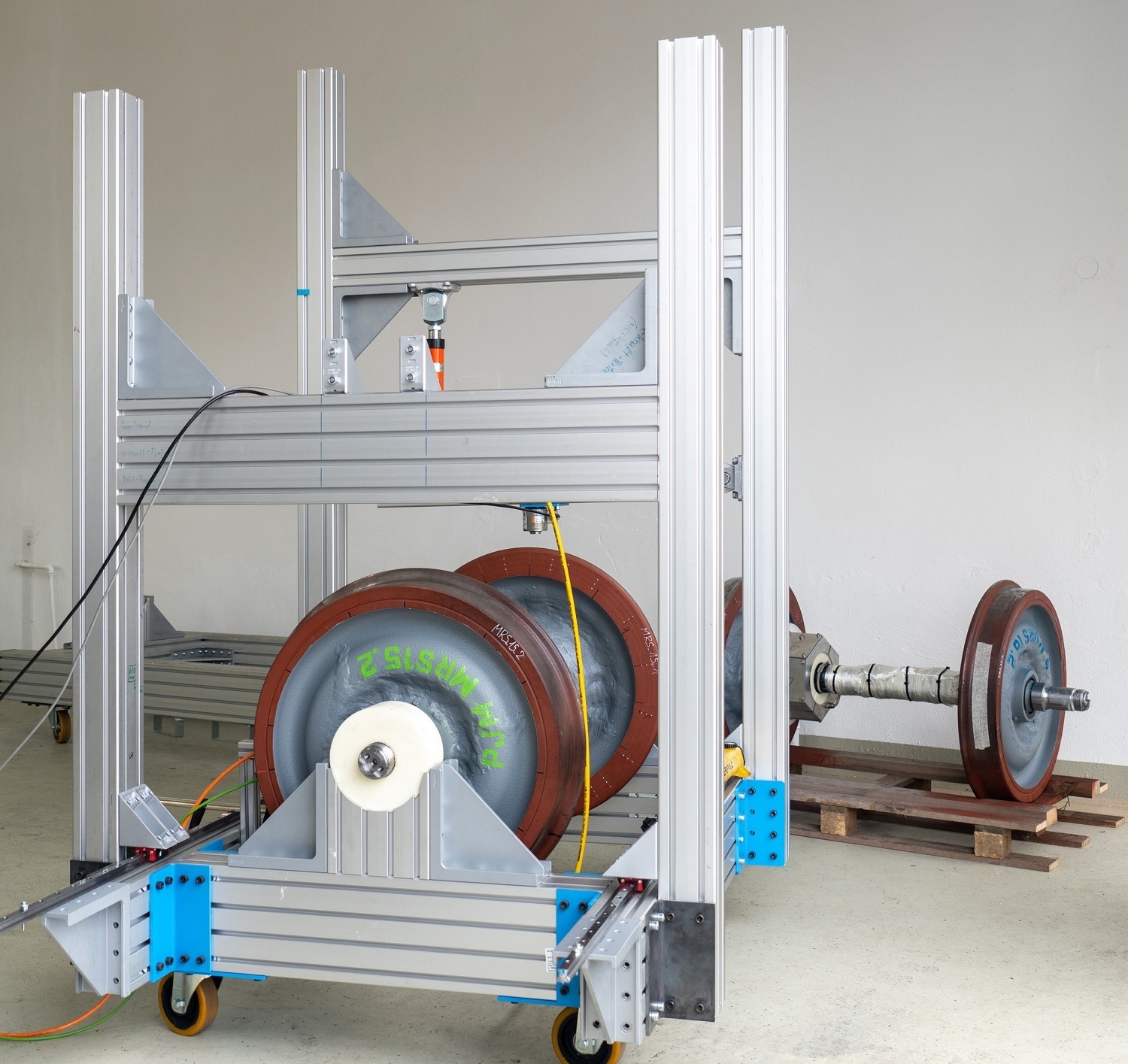

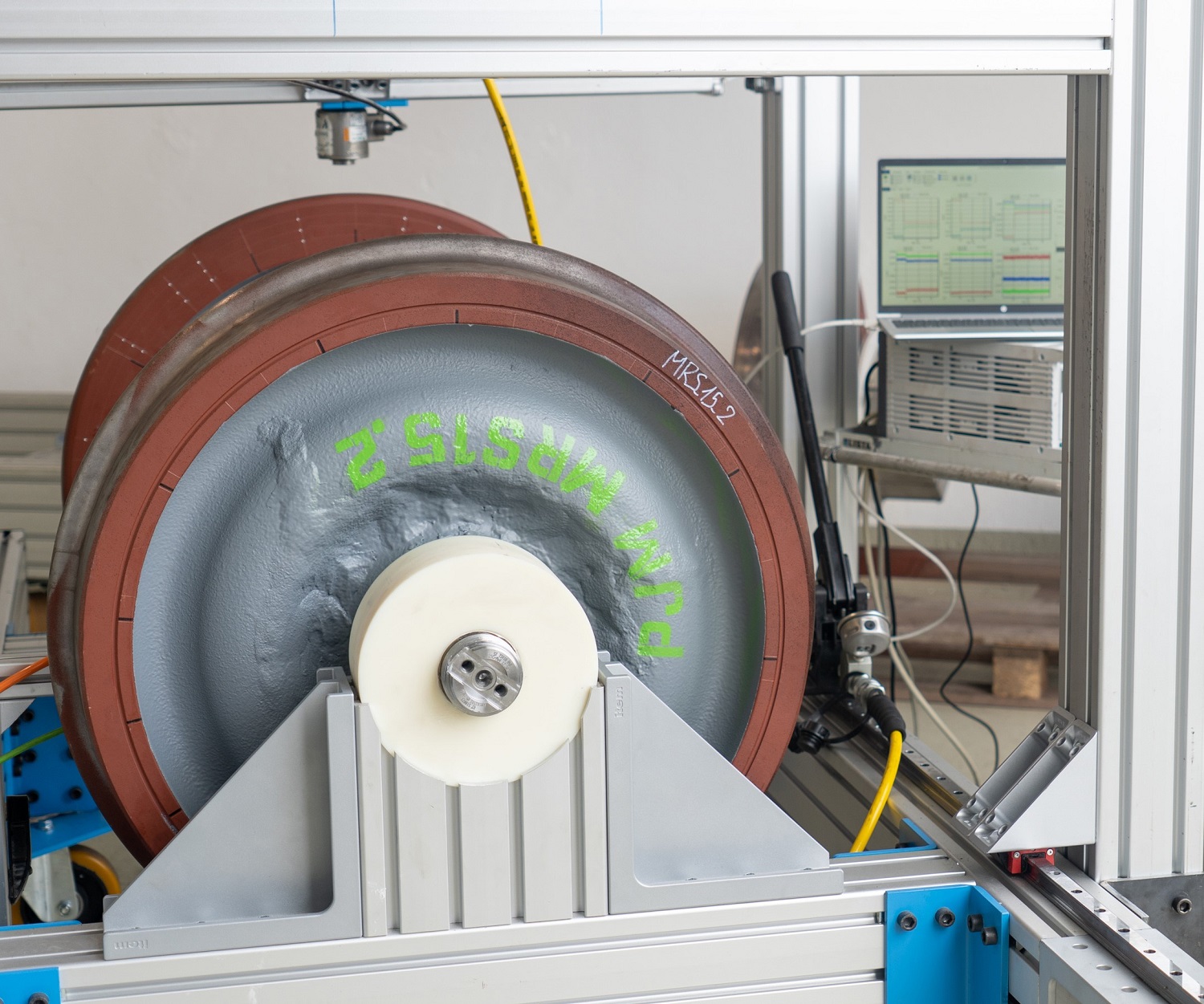

The fatigue strength tests are used to check that the rail vehicle can withstand the operational loads. There are different test methods for determining the operational strength, such as static tests or impact tests. An important part of this is the pressure frame test, in which the vehicle frame is subjected to loads in an empty and loaded state. The mobile compression frame has proved particularly effective in this respect. With PJM's own development, it is possible to carry out the tests directly at the manufacturer's premises and to use the infrastructure on site or in the vicinity. This was recently the case at Maschinenfabrik Liezen, which offers a perfect infrastructure. For an Italian wagon manufacturer, fatigue tests according to EN 12663 were carried out with the mobile pressure frame.