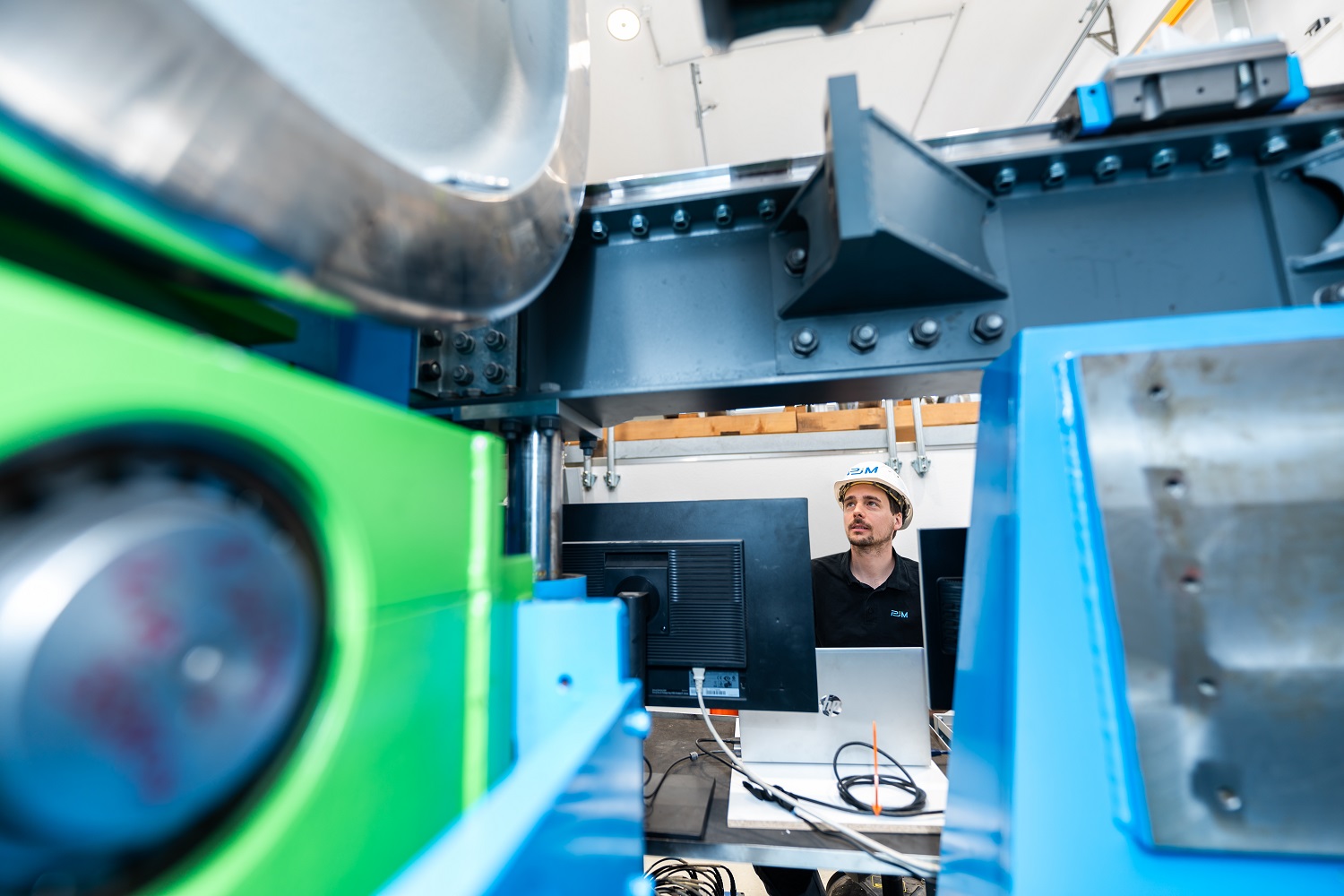

80 tonnes packed with sophisticated technology and one of the most beautiful railway lines in the world - these are the ingredients for a vehicle test by PJM in northern Europe. The Austrian measurement technology specialist was commissioned to test the brakes and acoustics of the Schmidt Beilhack HB 1100S, which will be used by Bane NOR in the future.

The track tests for the brakes were carried out in accordance with TSI LOC&PAS:2024, EN14033-1:2014 and NNTR-NOR. The first tests took place between autumn 2024 and April 2025 in a wide variety of weather scenarios and included, among other things:

- Wheel slide protection tests to determine braking distance and braking performance in Holmenstrand

- Steep gradient track tests on the Flam Railway and further test runs between Finse and Voss. The Flam Railway is one of the most beautiful train journeys in the world and is one of Norway‘s main tourist attractions. From a railway engineering perspective, the gradient is particularly interesting: the maximum gradient is 55 ‰.

Furthermore, PJM was commissioned to carry out acoustic measurements for employment protection (health and safety requirements). These tests will be carried out in autumn.

‘The tests for the approval of Aebi Schmidt‘s high-performance snow blower are another project for PJM involving special rail vehicles and railway construction machines. In recent years, we have tested various well-known special vehicles for approval in many parts of Europe,’ says Martin Joch, CEO of PJ Messtechnik GmbH.