GATX Rail Europe is pleased to announce its new partnership with PJ Monitoring (PJM), a respected player in the rail solutions industry. This collaboration, finalized during a recent workshop in Graz, is a strategic move to diversify and enhance our telematics sensor offerings. Through this partnership, GATX aims to provide our customers with greater capabilities to strengthen their rail operations in three areas.

1. Complementing Existing Telematics Solutions & Sensors

GATX will be introducing a new range of sensors that will enhance its current sensor portfolio. These additions are designed to optimize efficiency and safety. These enhancements will provide a new level of automation in rail logistics.

Johannes Friess, Head of Fleet Management at GATX Rail Europe, said, “We are known for our high-quality, modern railcar fleet and are now expanding our sensor portfolio with easy access to state-of-the-art sensor technology, paving the way for the next level of railway transport automation.”

2. Enhanced Overload Protection

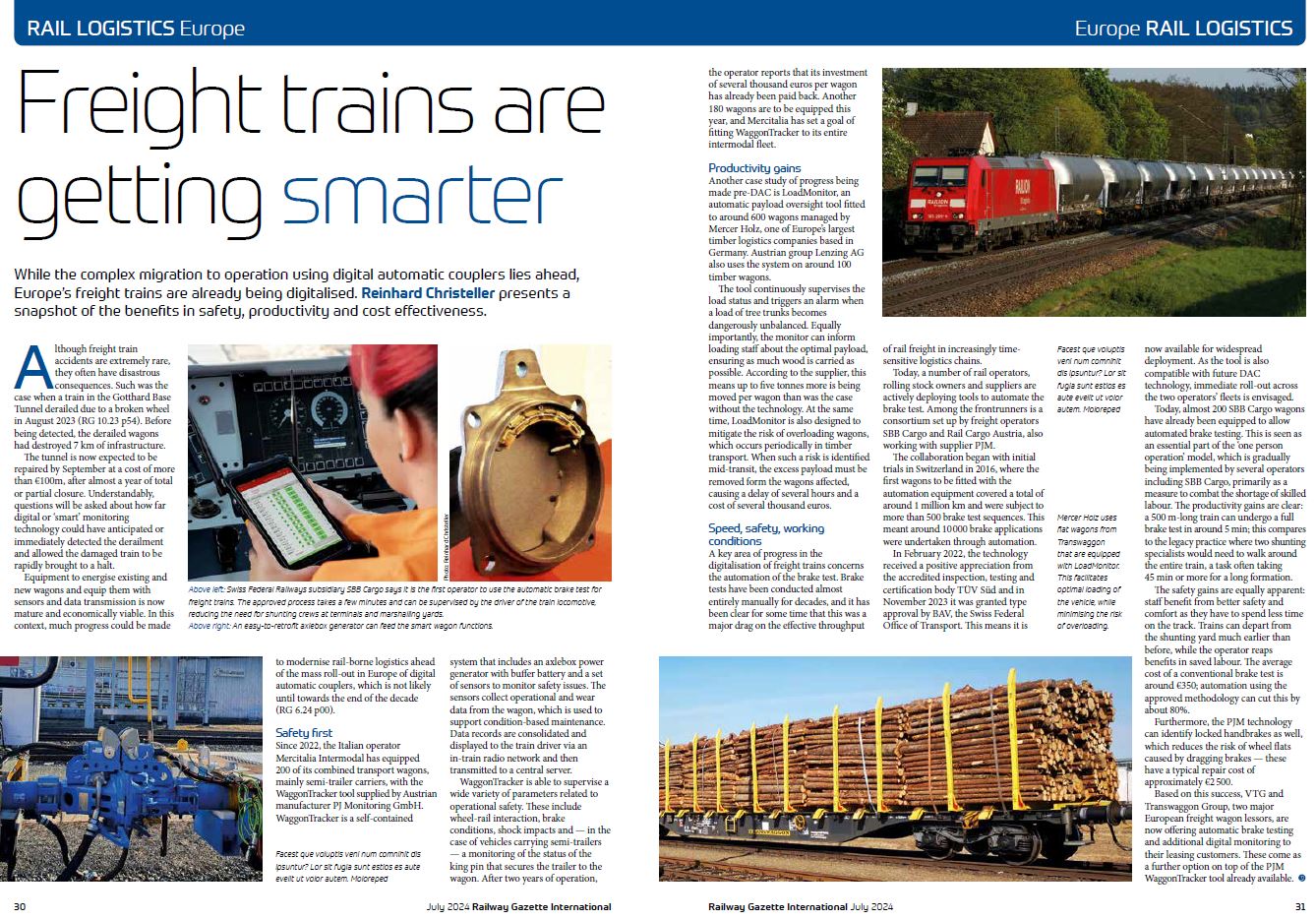

With the new Eanos & Eamnos railcars, GATX offers the option of using the overload protection sensors from PJM. This technology has been tried and tested on various wagon types over the years, demonstrating its effectiveness. The commitment is to increase its implementation and extend its usage to optimize the safety and efficiency of rail freight transport.

3. Innovative Automatic Brake Testing

In collaboration with PJM, GATX is also actively offering railcars with automatic brake test system equipment. This holds immense potential for our customers, giving them the means to significantly streamline their operations by saving time during brake tests. GATX Rail Europe views this initiative as more than just a singular solution; it represents a cross-sectoral development that has the potential to positively influence the entire railway market.

Günter Petschnig, Managing Director at PJM, said, “We are delighted to collaborate with the railcar experts at GATX Rail Europe on digitialization and automation solutions such as the brake testing and the load monitoring, because together we can increase the safety and efficiency of railway transports.”

Video on load monitoring system

Text provided by GATX Europe, photo by Markus Lang