Three countries, three stages, one mission: PJM showcases its expertise at top mobility events in the DACH region

Within just nine days, the PJM Group was represented at three specialist events relating to the mobility of the future - an impressive sign of the company's commitment and expertise in an increasingly changing sector. From Graz to Cologne to Basel, PJM presented its solutions and visions for efficient and sustainable rail transport - with an international audience and a strong industry presence.

Kick-off in Graz: Contact30 - Anniversary meets innovation

On 8 May, the event journey began at the ‘Contact30 Mobility Congress’ in Graz, the anniversary congress of the ACstyria mobility cluster, which celebrated its 30th anniversary. Around 700 guests from business, science and politics came together to discuss future mobility issues. PJM was part of the large exhibition with 86 companies of the ACstyria network and presented an impressive cross-section of its expertise in the field of rail systems. In addition, CEO Martin Joch of PJ Messtechnik GmbH joined a panel discussion and gave an outlook to future developments.

Digital focus in Cologne: The Rise of IoT & Big Data in Rail

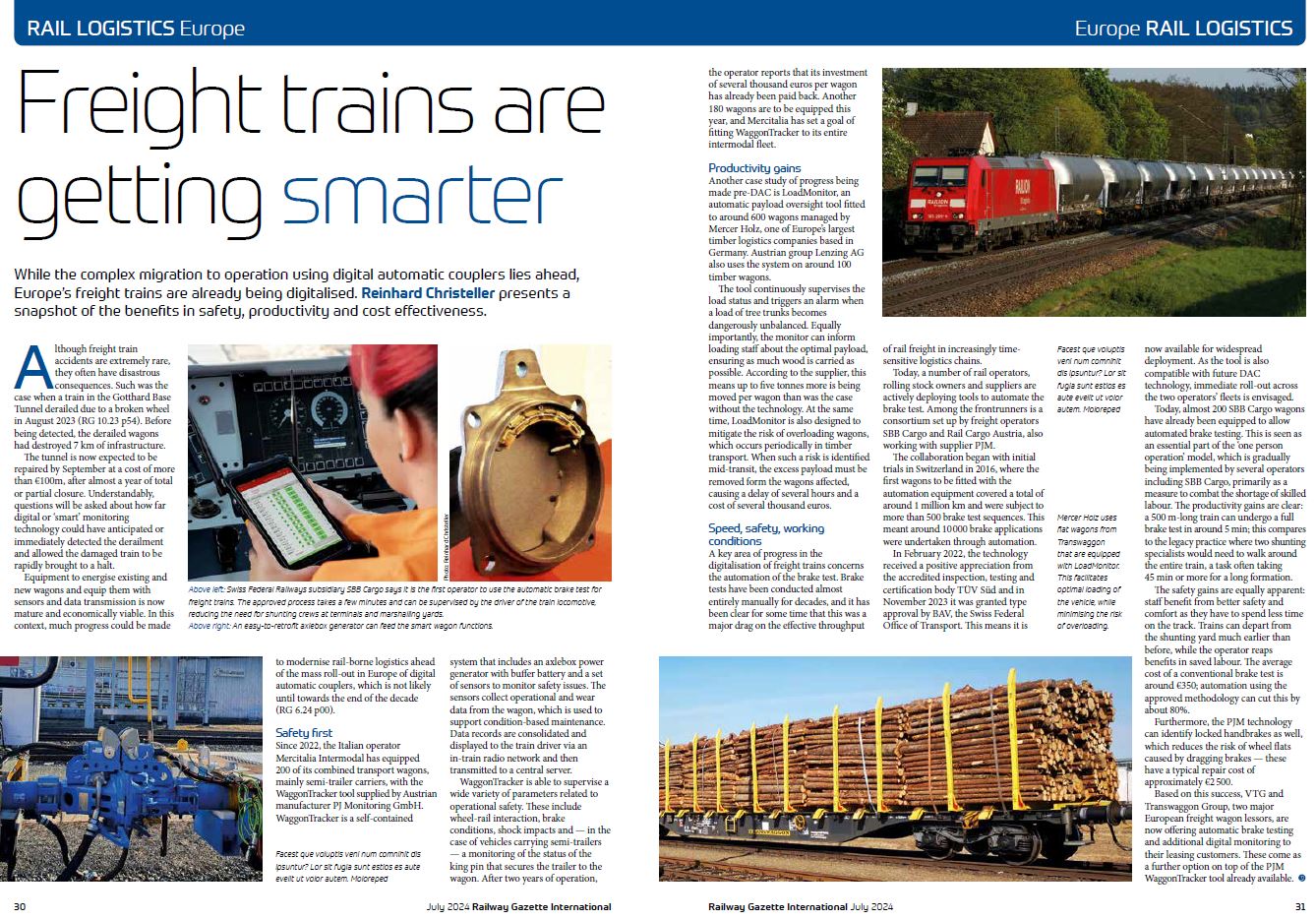

The journey continued seamlessly to Cologne for the specialist conference ‘The Rise of IoT & Big Data in Rail’ on 14 and 15 May. Hundreds of visitors from all over Europe took part in the event, which was all about the digital transformation of the rail industry. The focus was on issues such as how to improve the ravailability of rail operations, increase efficiency, optimise capacity and significantly reduce maintenance costs. At its own stand, PJM presented its pioneering WaggonTracker solution, which enables real-time brake analysis and monitoring, trestle monitoring, derailment diagnostics (IDDS) paired with in-train communication, load weight monitoring and automatic brake testing, among other things.

Visions of the future in Basel: Bahn25

Just one day later, on 16 May, PJM was represented at the renowned ‘Bahn25 Congress’ in Basel - the international summit on the freight transport of the future. Megatrends, innovation steps and strategies for the rail freight transport of the future were discussed with international trade visitors. The focus: a panel discussion with Alexander Muhm (Head of Freight Transport SBB Cargo), Ansgar Brockmeyer (S&M Deputy Group CEO Stadler Rail Management AG) and CEO Günter Petschnig with insights and impulses for rail freight in the next decade.

Conclusion: A strong presence for a strong future

With this extraordinary series of events, the PJM Group has impressively demonstrated its role as a forward-looking player in the rail industry. Three countries, three platforms, one clear signal: PJM is actively shaping the future of rail transport - innovatively, internationally and with full energy.

And the journey continues ...

Full of impressions, PJM is already looking ahead to the next stop: tranport logistic 2025 in Munich, the world's leading trade fair for logistics, mobility, IT and supply chain management, is the next highlight on the agenda from 2 to 5 June. Experts from the industry will once again come together there to discuss the mobility of tomorrow. PJM will once again be there with fresh ideas, technological excellence and clear messages - ready to continue the dialogue and help shape the future of rail.