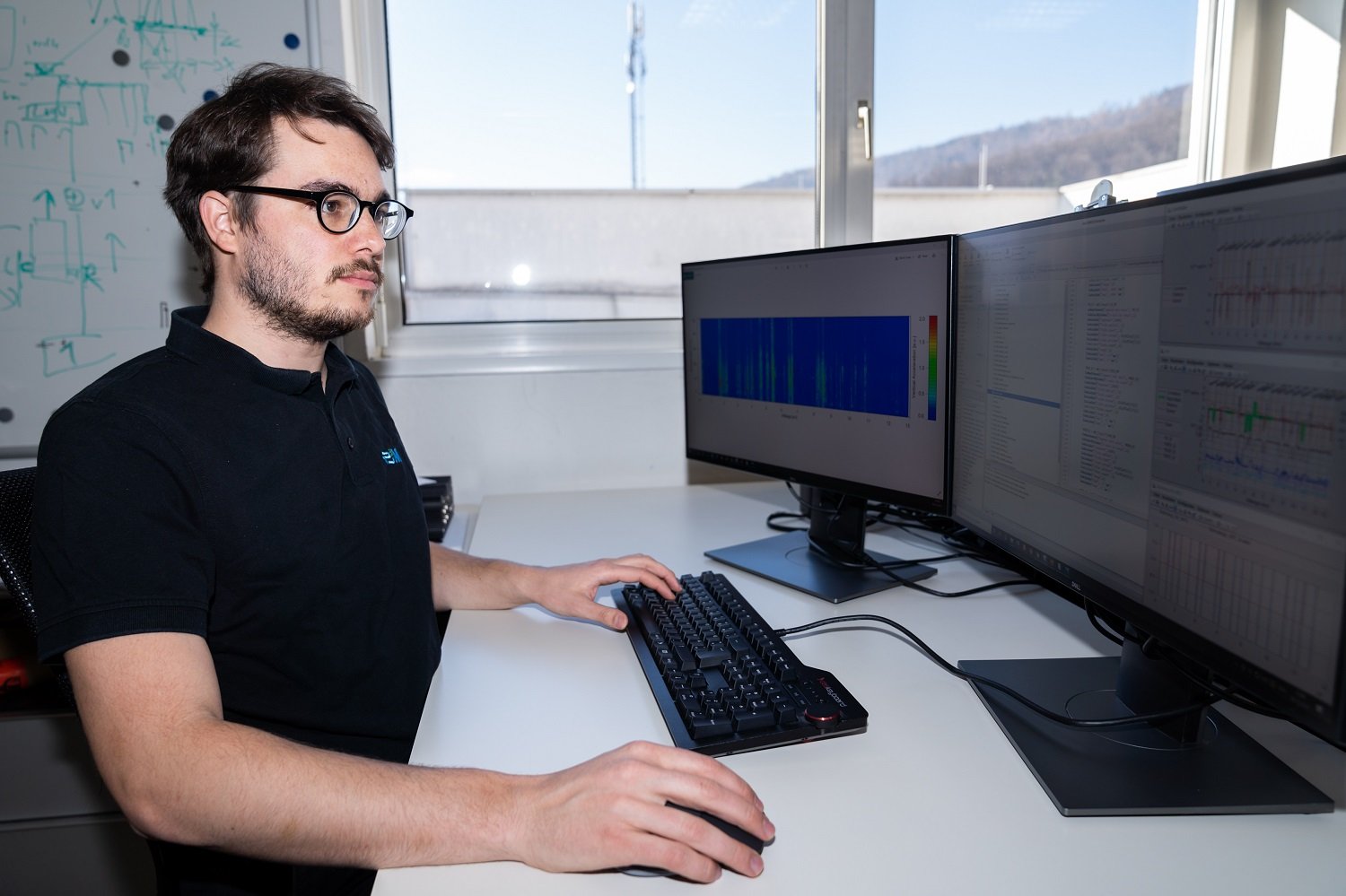

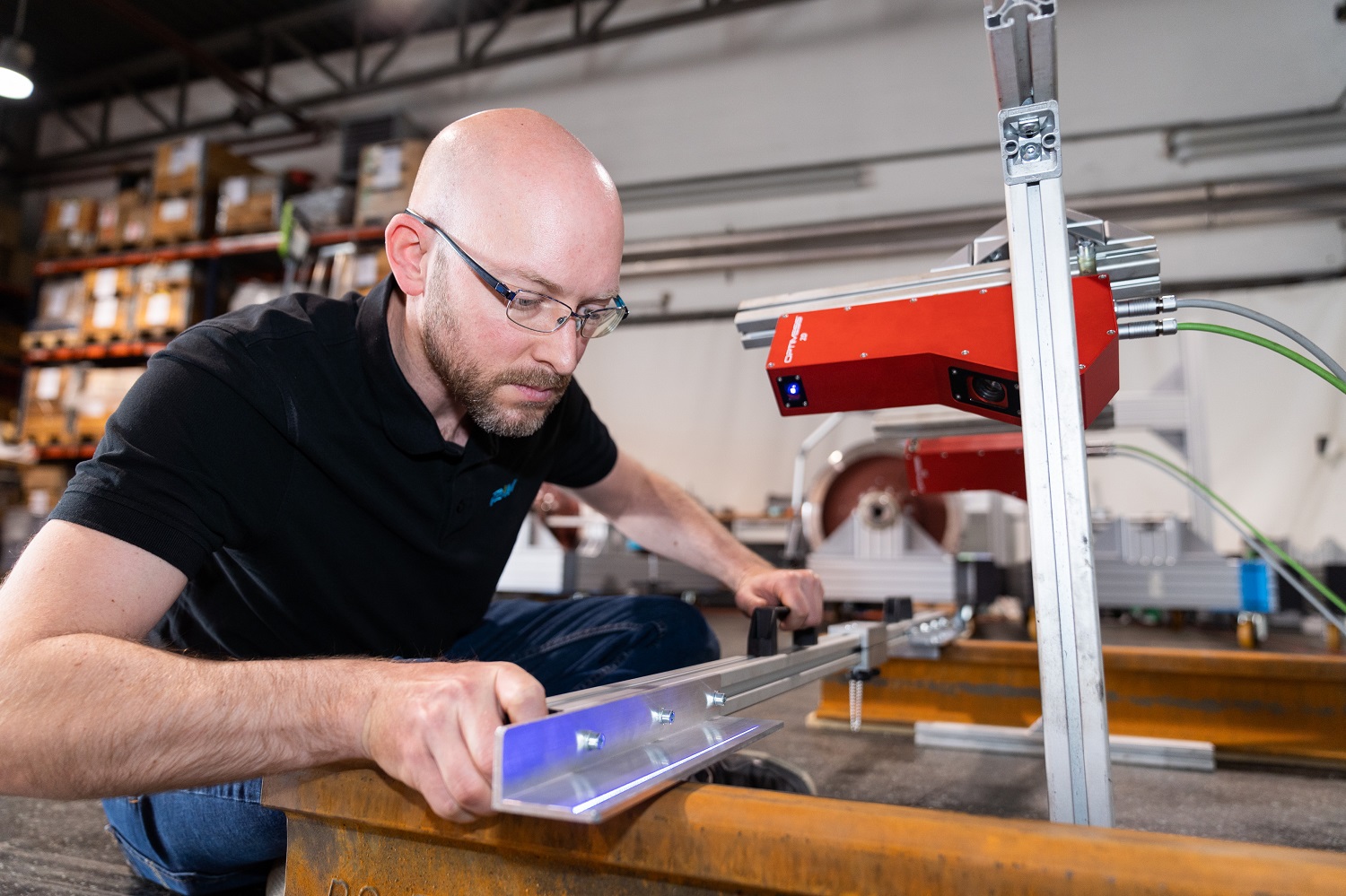

The ideal summer reading: The technical article published by the renowned railway magazine ETR and produced by experts on the subject of milling technology from voestalpine Track Solutions Germany GmbH and from our measurement technology team. The new and unique concept involves network-wide recording of the rail condition with the aid of state-of-the-art sensor technology. Subsequently, targeted rail milling work is carried out on tracks and switches. The project was awarded the Austrian State Prize for Engineering Consulting in the spring.

Get the full article (in German language): https://pjm.co.at/en/wp-content/uploads/sites/2/2022/08/ETR_Schieneninstandhaltung_Barcelona_voestalpine_PJM0322Web.pdf