Export Award 2022 goes to PJM: The digitization platform WaggonTracker with the application of automatic brake testing convinced the jury of experts

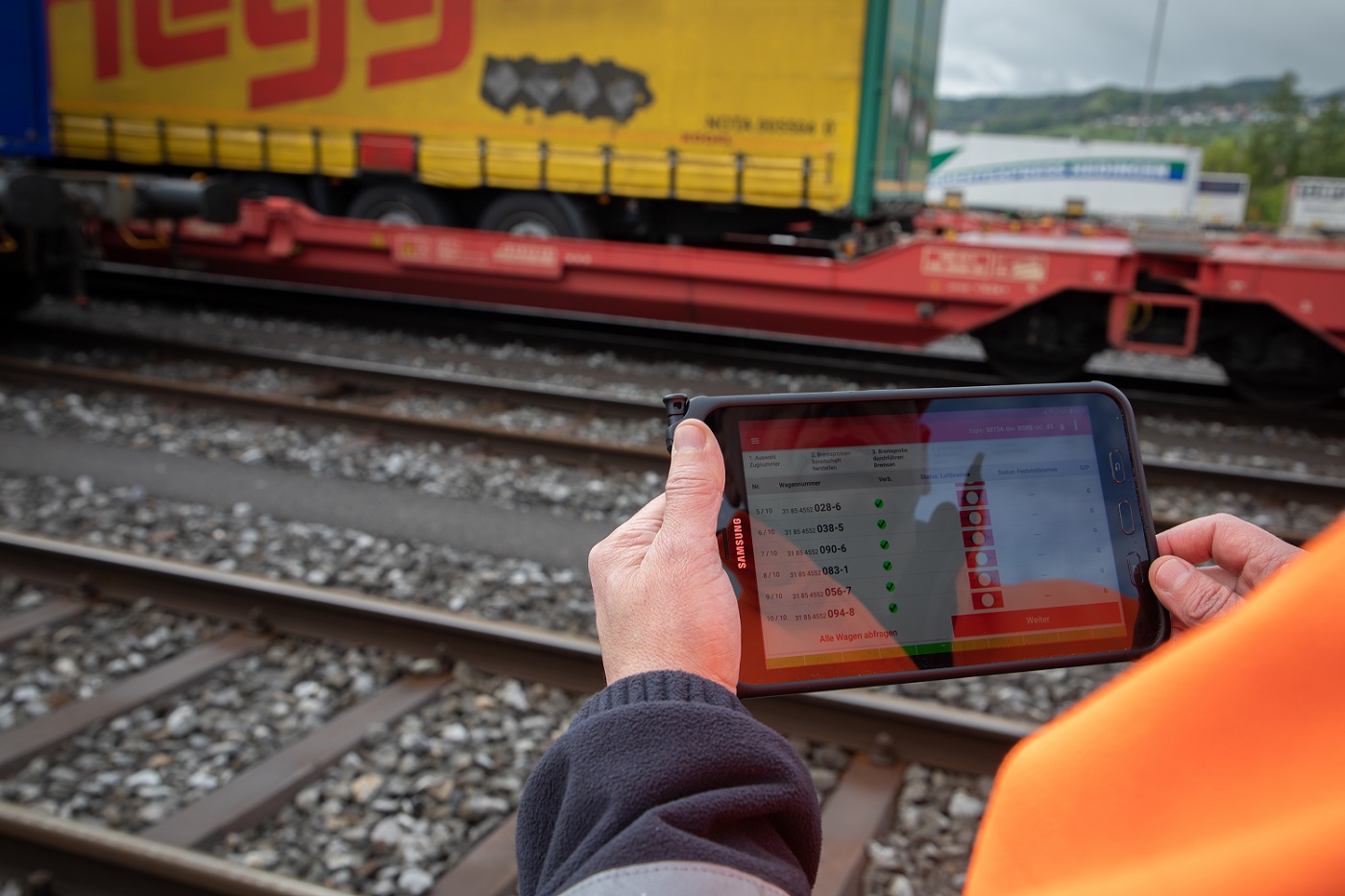

The most successful exporters are brought to the stage every year. The export award, which honors innovation, market potential and export quota, among other things, was presented on June 27th. PJM was awarded gold in the Information & Consulting category. The deciding factor was the overall digital system WaggonTracker, which makes automated rail transport a reality. This includes automated brake testing for freight trains. The automated system is the first in Europe to be fully developed and to receive a positive review. "The challenge was to automate a safety-relevant process. We saw the realization of our brake test system through to the last required document. The reward for our many years of development work is the successful market entry," says CEO Martin Joch.

The 2022 Export Award was presented in five categories at a ceremony in Vienna's Museumsquartier. Despite the global lockdowns and restrictions caused by the Corona pandemic, many Austrian companies were also successful in exporting their goods and services internationally in the previous year. "These companies are drivers of growth, jobs and prosperity in Austria. Every second job in Austria depends directly or indirectly on the export success of these companies. Every year, the Export Award honors companies for their special export achievements," emphasizes WKÖ President Harald Mahrer.

"Austrian companies are role models and pioneers - especially in the field of environmental technology. They are innovative and in many cases also world market leaders in their field," Kühnel emphasized the special achievements of domestic companies.

"Our winners this year demonstrate how digitalization is being used as a means of shaping a sustainable future. This innovative strength of Austrian companies is increasingly being recognized on the global market," said deputy chairman of the federal division Martin Heimhilcher, congratulating the winners.

Quellen:

Credit: © FRANK HELMRICH PHOTOGRAPHIE

Already the 3rd award for PJM in this year

The export price is already the 3rd honor in this year for PJM. Last week in Utrecht (NL) the RailTech Innovation Award (audience award category) was presented to PJM. The Automatic Brake Test was also awarded. In May, a metrology project for Barcelona Metro was awarded the State Prize for Engineering Consulting.