PJM was awarded the Austrian National Award for Engineering Consulting 2021 on May, 11th. The submitted project convinced the 13 experts of the expert jury chaired by DI Dr. Peter Holzer.

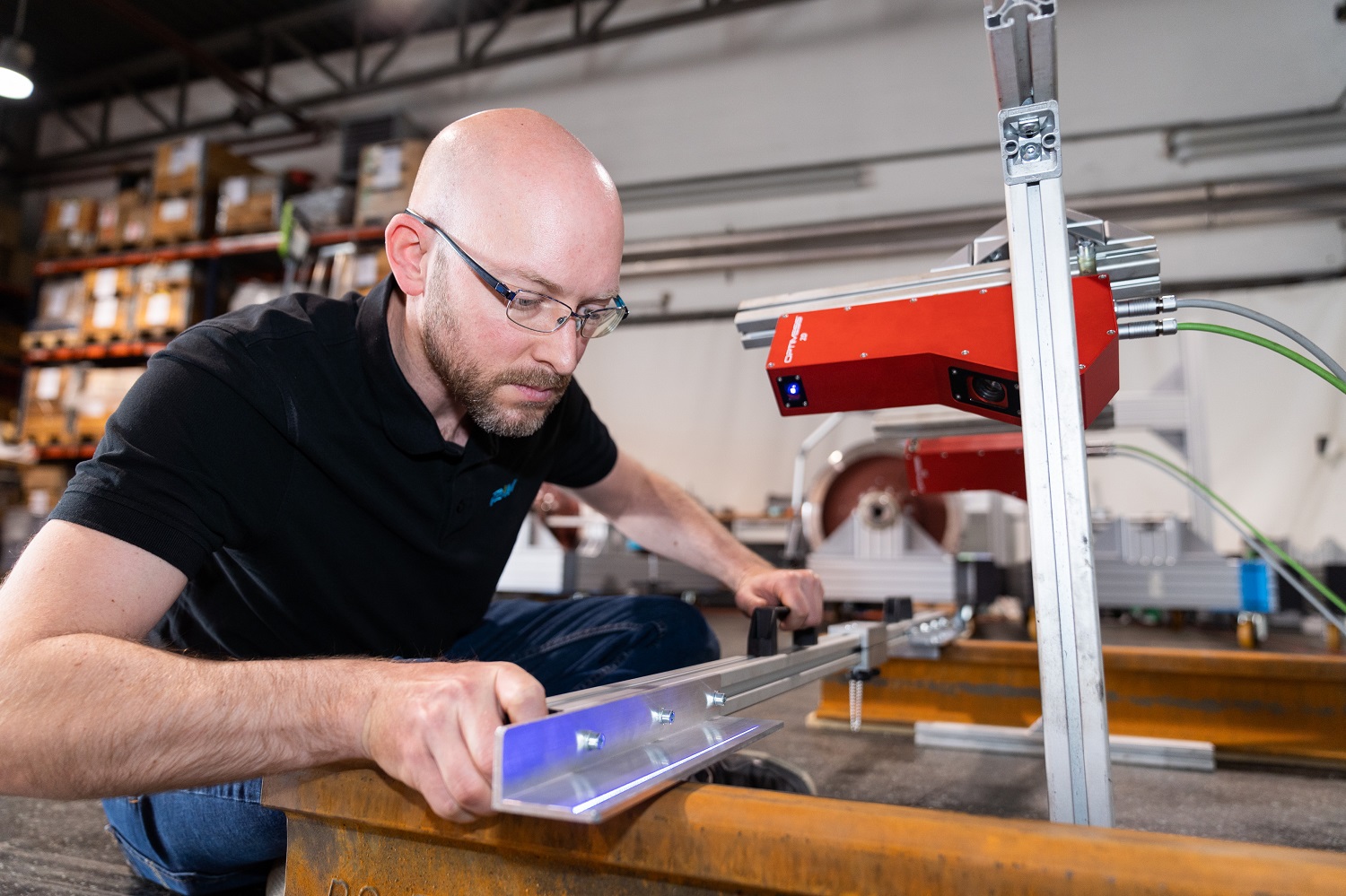

A new technical procedure was developed, which was applied among others for the Barcelona metro, with which the rails and tracks of city railways and underground trains can be measured smartly and digitally in a short time. For this, mobile measuring technology is used that is installed on an existing vehicle - instead of conventional measuring trains. These cannot be used for urban railways due to the smaller clearance gauge profiles. "The jury is unanimously convinced that the attractiveness of inner-city public transport can be increased with this technology, because the availability, safety and comfort of passengers is significantly increased", states the jury.

"What a great award! The expert jury looked at our solution in detail and asked well-founded questions. The State Prize is a wonderful confirmation of our daily striving for reliable solutions and innovative concepts. A big thank you also to our client voestalpine Tracking Solutions Germany GmbH," says Martin Joch, CEO of PJM.

About the State Prize

The State Prize for Consulting has been awarded by the Ministry of Economics since 1990, since 2010 alternately for "Engineering Consulting" (organiser: Austrian Consultants Association - ACA) and for "Management Consulting and Information Technology".

The awarded project

- Project by PJ Messtechnik GmbH: Efficient maintenance of rail maintenance using mobile measuring technology

- Client: voestalpine Tracking Solutions Germany GmbH

- Detailed information on the Metro Barcelona project: https://pjm.co.at/en/blog/2022/03/28/metro-barcelona-mobile-rail-milling-and-monitoring-project-successfully-completed-by-voestalpine-and-pjm

Photos: With courtesy of BMDW © Silveri Matthias