Mercitalia Intermodal, a company of Polo Logistica FS, and PJM have signed a new order on further fleet equipment with smart train functionalities. Specifically, approximately 600 intermodal wagons will be equipped with PJM’s overall digital WaggonTracker system as part of maintenance work.

In addition to general wagon monitoring (speed, running direction, geofencing, wheelset performance management, last signal, last movement, etc.), the functionalities also include real-time brake monitoring, real-time kingpin monitoring and IDDS derailment detection system. A local radio system within the train set ensures direct communication in real time between the wagons and the train driver. The in-train communication is based on an encrypted, secure connection and open interfaces. The WaggonTracker system is fully compatible with a future DAC system and can be expanded with customized applications thanks to the powerful power supply. The innovative strength of the overall digital system is evidenced by multiple awards, such as the State Prize for Digitalization.

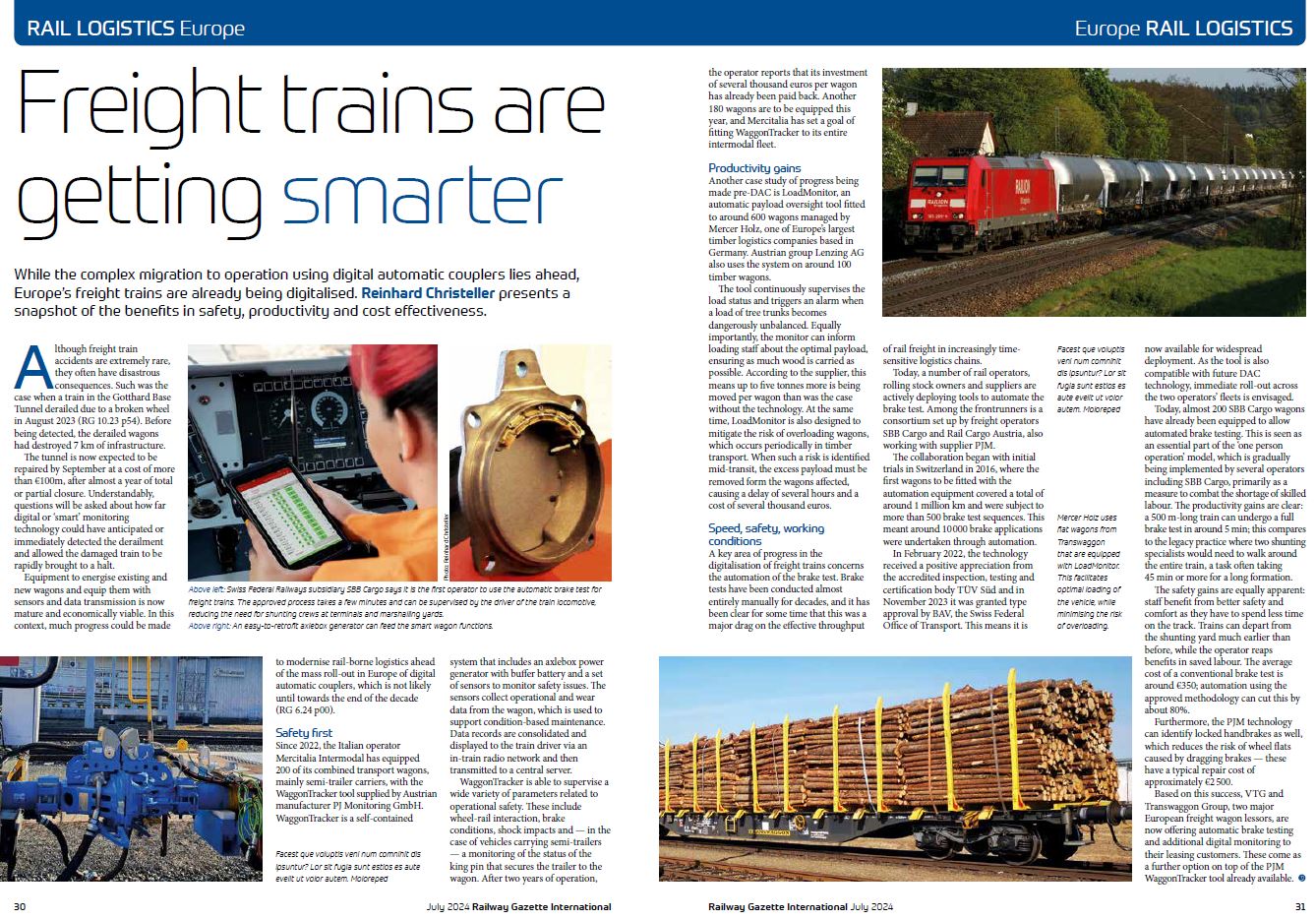

The Italian wagon keeper has been focusing on the digitalization of its intermodal fleet for several years in order to achieve the optimum in rail logistics between the conflicting priorities of cost-effectiveness, availability and safety. The smart train functions are essential as they bring improvements on several levels. Train preparation is shortened, asset management and maintenance work are optimized thanks to a predictive maintenance strategy, reliability is increased, vehicle-friendly operation is made possible and short-term resulting in cost-intensive repair work is minimized. These economic optimizations are supplemented by an increase in safety.

Sabrina De Filippis, CEO of Mercitalia Logistics, said: “Innovation and digitalization are two of the enabling factors of our 2025-2029 strategic plan, which includes investments dedicated to digitalization, also thanks to innovative projects such as the smart train. We are constantly committed to adopting cutting-edge technologies to significantly reduce the environmental impact of logistics operations, while ensuring a high-quality service. The smart train is one of the projects that will allow Mercitalia Logistics to become a European logistics player, contributing to the evolution of global logistics”.