PJM und Boom Software utilising the connecting railway of a decommissioned coal-fired power station as a test site for innovations in the rail industry. This purpose has led to the foundation of the joint venture INFRATRACK Solutions.

The two railway specialists Boom Software AG and PJ Messtechnik GmbH have taken over the connecting railway line at the Mellach Verbund power plant site. This cooperation will allow the existing rail infrastructure of the decommissioned coal-fired power plant to be used more intensively, particularly for testing purposes.

Located in the immediate vicinity of Graz and the new Koralmbahn railway line, as well as the two Styrian companies, the site will be home to innovations and further developments in the railway sector, particularly in the fields of measurement and testing technology and software.

The optimally located and equipped connecting railway line provides an ideal environment for testing rail vehicles and components. The range of activities extends from physical asset inspections to sensor- and software-based testing.

Image:

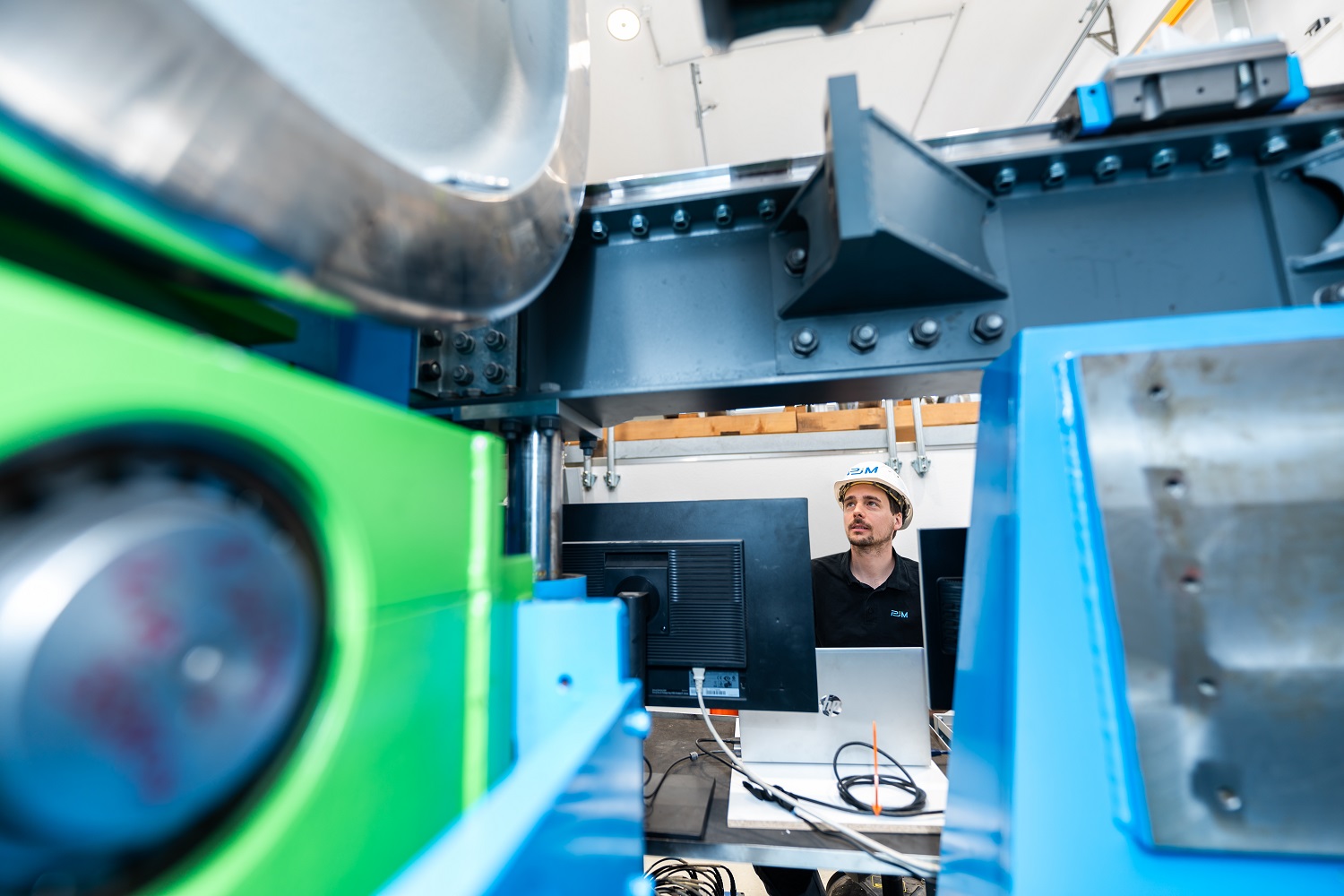

The new company's managing directors Andreas Schaller (left) and Martin Joch (right)